China scientists develop coating that can keep knives sharp for 100 times longer

Chinese scientists say they have developed a coating that keeps a knife sharp 100 times longer than one without the material.

Chinese scientists say they have developed a coating that keeps a knife sharp 100 times longer than one without the material.

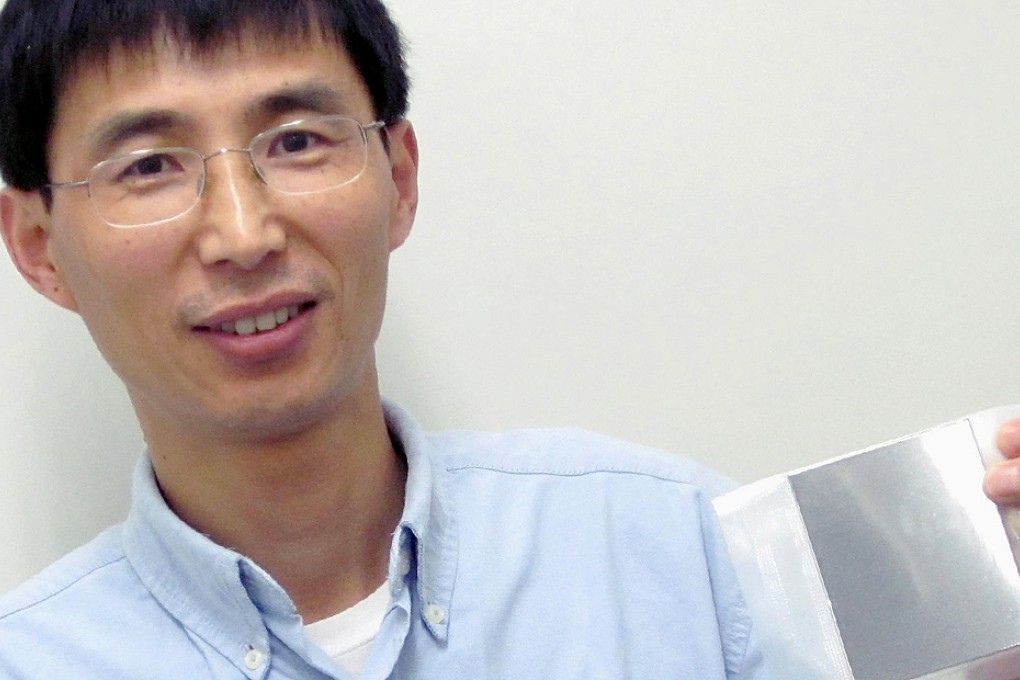

The anti-wear coating was developed by a team headed by Huang Feng, a professor at the Chinese Academy of Sciences' Ningbo Institute of Material Technology and Engineering.

Huang said the film could be applied to more than just kitchen knives - it could also be used in manufacturing, potentially increasing product lifespan and boosting the competiveness of heavy industry.

It takes 1,000 grindings, under the force of 10,000 times the atmospheric pressure, to wear off one layer of atoms of the anti-wear coating, the team says. "If applied to a kitchen knife, the lifespan of the knife may be extended beyond the life of its user," Huang told the South China Morning Post.

The coating is made of various nitrogenised metals such as chrome and vanadium. It was a few micrometres thin and could be applied to the surface of almost any machine, Huang said.

The material could have applications in aviation and carmaking. Chinese manufacturers tend to use anti-corrosive coatings from Europe, especially Germany, to prolong the life of machines and maintain production line quality.