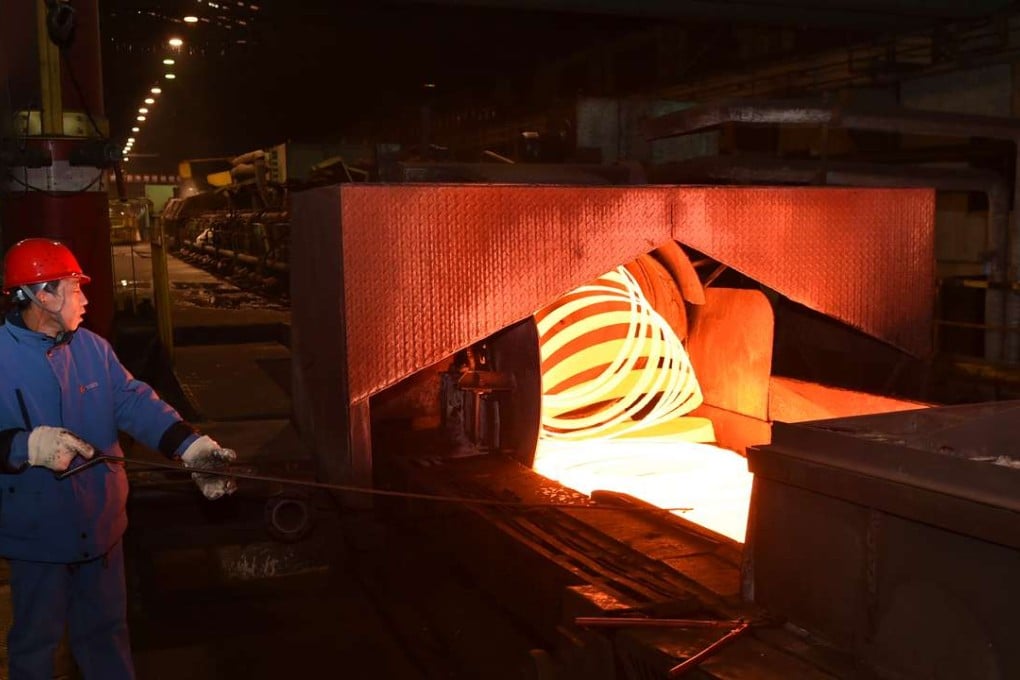

Update | Why cracking the secret of the ball-point pen is such a big deal for Taiyuan Steel

More steel product successes seen possible after ball-point pen ‘breakthrough’

Taiyuan Iron & Steel Group’s recent breakthrough in producing the metal ball casing for ball-point pens could herald more technological advancement by Chinese steel producers to reduce imports for some key products, according to analysts.

The breakthrough has allowed the industry to get around its reliance on foreign suppliers of a key component in one industry, but more needs to be done for Chinese industry to churn out high value-added products amid overcapacity of low-end products.

But to speed up technological breakthroughs, they might have to raise the effectiveness of their research and development spending, while the government could foster greater research spending of smaller firms by improving legal protection for intellectual properties, they said.

Wu Wenzhang, chairman of industry consultancy Shanghai SteelHome, said the Chinese steel industry, the world’s largest, had ample research capacity, including in the technology-intensive aerospace, oil and gas, and car sectors.

“The product development capabilities of China’s steel industry are pretty strong,” he said. “Where the momentum is lacking is that new product investment is primarily made by the large steel mills and not the medium and small ones ... Investment has been held back by concerns that intellectual property would be stolen and that returns may not cover investment.”

State-owned Taiyuan Steel said in a statement in January that after five years of research and development, it had come up with the right materials composition to mass-produce the steel needed to make the “ball socket” that held the freely rotating metal ball at the tip of a ball-point pen, whose movement within the socket allowed the ink to be dispensed.