To stay relevant, Hong Kong port unveils remote-controlled cranes

Hongkong International Terminals has installed 29 automated gantry cranes at Terminal 9 as part of a HK$2 billion technology upgrade programme

The move by Hongkong International Terminals (HIT) to install remote-controlled gantry cranes at Kwai Tsing container terminal will go a long way in improving the working conditions of its crane operators but will hardly improve the competitiveness of the city’s port.

HIT, the city’s leading port operator, has equipped its revamped Terminal 9 North with 29 remote-controlled gantry cranes, narrowing the technological gap with ports such as Qingdao in China where the day to day operations are fully automated.

Hong Kong was once the world’s busiest port in the 1990s all the way until 2005. But as ports in mainland China and Singapore emerged over the past two decades, the competitiveness of the city’s port significantly diminished. Now ranked as the fifth busiest for port throughput, Hong Kong port trails behind those in Shanghai, Singapore, Shenzhen and Ningbo.

Franco Ning, HIT’s general manager of operation, said the implementation of remote-controlled cranes is aimed at improving the work conditions of crane operators and attracting new talent.

“Last year, we lost about 30 per cent of our crane operators,” he said.

Lothair Lam Ming-fung, vice-president of Parakou Shipping, said port operators such as HIT were struggling to hire technicians like crane operators and lorry drivers, pointing to the fact that the average age of this group is between the ages of 50 and 60.

That the port is struggling to hire and retain its workforce is not new. Dock workers went on a 40-day labour strike in 2013 to demand better pay and working conditions, following which they were promised a pay rise.

Ning said the installation of the new remote-controlled cranes would allow crane operators to manoeuvre them from a more comfortable office environment rather than in a crane cabin, thereby also improving occupational safety.

He added that this was part of the company’s HK$2 billion (US$256 million) investment plan to upgrade the technology of the port.

“It took us four years to implement this because there is still a gap between our port, which is very old, and the new ones which are designed for remote-control from the ground up,” he said.

In addition to the new cranes, the company is also introducing an automated container stacking system.

HIT said with the new operation system in place, the cranes will be 20 per cent more efficient, which will reduce the use of electricity and cut carbon dioxide emissions by 30 per cent.

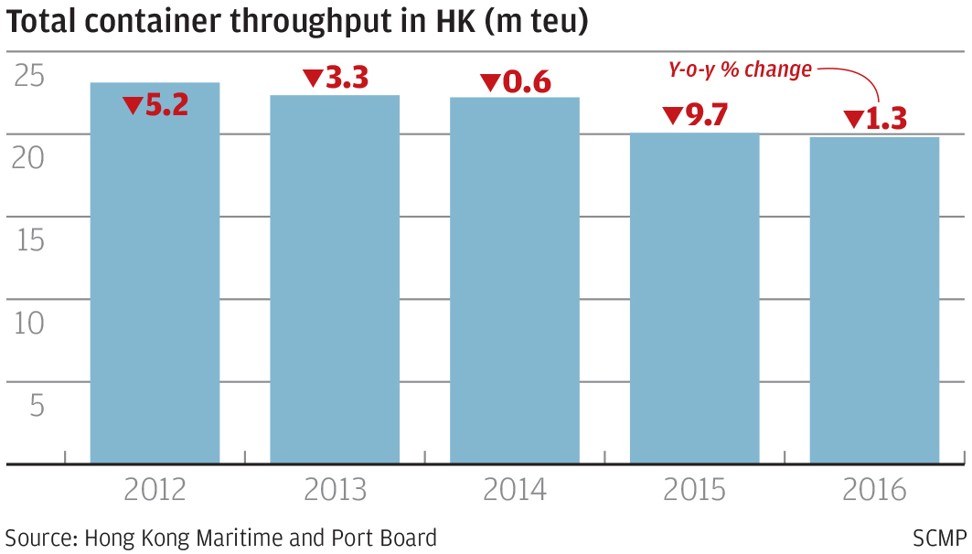

Lam, however, noted that despite the new measures put in place to make Hong Kong Port more competitive, the use of the port has continued to fall since 2011. Its throughput dipped to 19.8 million twenty-foot equivalent units in 2016, 20 per cent lower than the volume in 2011 when the decline started.

It makes very little sense for CK Hutchison Holdings, which owns HIT, to continue to invest in Kwai Tsing container terminals, he said.

“If anything, CK Hutchison would be more incentivised to develop its port in Shenzhen. The port in Shenzhen is much more mouldable and they are launching new phases of development.”