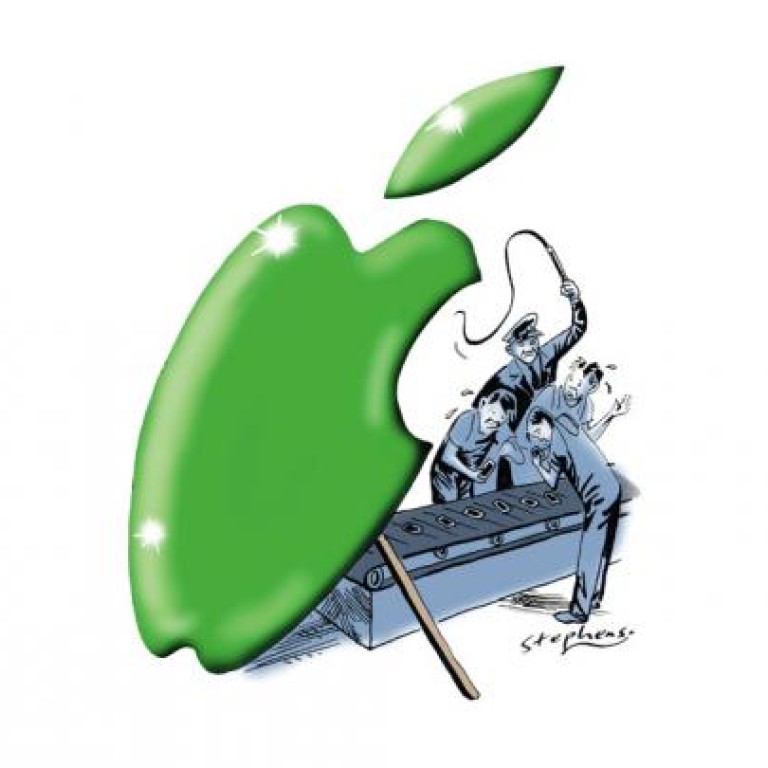

The high costs of an iPhone

Li Qiang says Chinese workers are paying a heavy price for Apple's insistence that suppliers churn out its latest products as quickly as possible to meet insatiable consumer demand

Apple's iPhone 5 sold out in its first weekend, with consumers buying over 5 million units. But if you were hoping to get one, don't worry, because Apple chief executive Tim Cook has assured us that, "We are working hard to get an iPhone 5 into the hands of every customer who wants one as quickly as possible."

But when Apple executives say "we", they actually mean their Chinese manufacturing workers. It is these factory workers who are "working hard" - more accurately, doing whatever it takes - to produce enough phones "as quickly as possible".

Whatever it takes is often too much. The recent violent conflict that erupted at an Apple supplier factory producing iPhone 5's in Taiyuan, Shanxi, was rooted in the pressure put on workers to meet Apple's production demands.

Furthermore, the riot reflects a tragic consequence of Apple's marketing strategy and rapid production model: workers pay the price.

The time period between Apple's announcement of a new product and the sale of that product is extremely short, causing a spike in demand from consumers. As millions of orders pour in for a new product, Apple puts tremendous pressure on its supplier factories in China to rapidly meet production demands. This means quickly hiring waves of new young workers who must work long, extraordinarily demanding hours, without enough time to be properly trained.

The costs of this rapid production are borne by workers. For example, China Labour Watch investigators found that in Apple's supplier factory in Zhengzhou, Henan, a production line of 87 workers was expected to assemble 3,000 iPhones a day in August.

But after last month's announcement of the iPhone 5, the same number of workers was expected to assemble 6,500 phones a day in the same amount of time; the workers are still struggling to meet this work requirement - over 10 hours a day, six days a week.

This sort of pressure has tragic consequences. In 2010, there were 13 suicides at Foxconn. In May last year, an explosion at Apple's supplier in Chengdu resulted in four deaths and 18 injuries. In December, another explosion at an Apple supplier in Shanghai injured 61 people.

The riot in Taiyuan occurred in the context of a squeeze on workers to fill massive orders very quickly. On September 12, Apple announced the coming release of the iPhone 5. And just nine days later, it planned to begin delivering orders.

According to China Labour Watch investigations, in trying to meet the demands of Apple's rapid production model, the norm for workers at Foxconn factories like Taiyuan are 10-hour day and night shifts with little rest and a rapid rate of work - all the while suffering the verbal and physical abuse of managers and guards.

Often in their late teens or early 20s, these young workers are pushed to the edge by so much stress. In Taiyuan, it only took the bullying of one worker by a few guards to ignite over 2,000 workers into violence, resulting in 40 being injured.

Not long after that riot, a strike occurred at Foxconn's Zhengzhou factory. In addition to demanding that people work during the holiday, Foxconn raised overly strict demands on product quality without providing additional training. This led to workers turning out products that did not meet the required standards, and this put tremendous pressure on them.

Additionally, it led to conflict between quality control inspectors and the workers, which several times resulted in the inspectors being beaten up. Factory management turned a deaf ear to complaints about these conflicts and took no corrective measures. The result was a widespread stoppage on the factory floor involving both the workers and inspectors.

Just as in previous incidents, the international media was quick to cover the Zhengzhou strike, and Apple was in every headline. But after the negative headlines fade, only the heightened publicity around Apple will remain.

And, while such incidents occur with disturbing regularity, Apple has failed to sufficiently reform its production and marketing model. Perhaps this is because the model is so profitable. Apple's profits now amount to tens of billions of dollars per year, and its share price hit US$700 last month.

Throughout, Apple has relied on factory workers employed in harsh conditions for little pay. The company needs to change its manufacturing ways. It should no longer meet its promises to consumers by violating the rights of the low-paid workers making its products. Otherwise, what we have witnessed may be just the beginning.