How Hong Kong fashion brand Isabella Wren’s body scanners help create the perfect fit for professional women

It used to take a person up to an hour to make a pattern; now it can be done instantly, and error-free, at the touch of a button at Hong Kong fashion house

Military parka gets a new lease of life thanks to Italian designer’s luxe twist on an old classic

While these offer a glimpse into the not-too-distant future, Hong Kong women’s wear brand Isabella Wren is making waves by offering women beautifully crafted, custom-made apparel with the click of a button.

“We use the best aspects of the handmade process and technology. Nothing like this system exists anywhere,” says CEO and founder Sarah Chessis. “This isn’t gimmicky, it’s real and tangible. This technology only becomes available when it’s available, so you have to be on top of it.”

Chessis isn’t a trained fashion designer – in fact, in her former life she was a successful stockbroker for almost 20 years. Her fashion experiences were limited to meetings with tailors, who she would task with creating clothes for her work wardrobe.

Finding it increasingly difficult to track down good tailors that specialised in women’s clothing, she decided to take matters into her own hands in 2013.

Fashion goes hi-tech with smart bags and watches, pollution-absorbing swimwear

“I moved back to Hong Kong to work with a client in China who wanted to roll out a custom-made business online,” she says. “It became apparent that it wasn’t about custom clothing, so I made the decision to do it on my own.

“Isabella Wren’s mission is to be the number one brand globally offering professional women’s clothing they can customise. That’s where I think there is a massive gap.”

Initially, Chessis teamed up with a designer to create a small collection of work wear that women could adjust according to their needs. Available in the brand’s showroom in Hong Kong’s Central district, the line features about 10 styles that she describes as traditional but edgy. It includes jackets, blouses, trousers, dresses and a skirt, with the option to change anything, from the sleeve style and length to the colour and fabric. A limited range of pre-selected fabrics is available, with two new fabrics launched every month.

Shanghai street style is exploding – from Wang Lili to Timothy Parent, meet the people who are shaping the scene

Because the garments are made to order, prices are on the higher end of the scale, ranging from HK$4,000 for a dress and HK$5,500 for a jacket, to HK$8,500 for a suit.

New to the fashion industry, Chessis has encountered plenty of issues along the way, including manufacturing.

We have been able to eliminate human error so that we can create patterns in an instant using an algorithm.

As the items couldn’t be mass produced and quantities were small, she eventually set up her own workshop so she could control the supply chain. Fit, however, proved to be the biggest challenge, with items having to go through up to eight adjustments before being sold.

It was only when she was tasked to make a uniform prototype for a five-star hotel that she considered technology a possible solution.

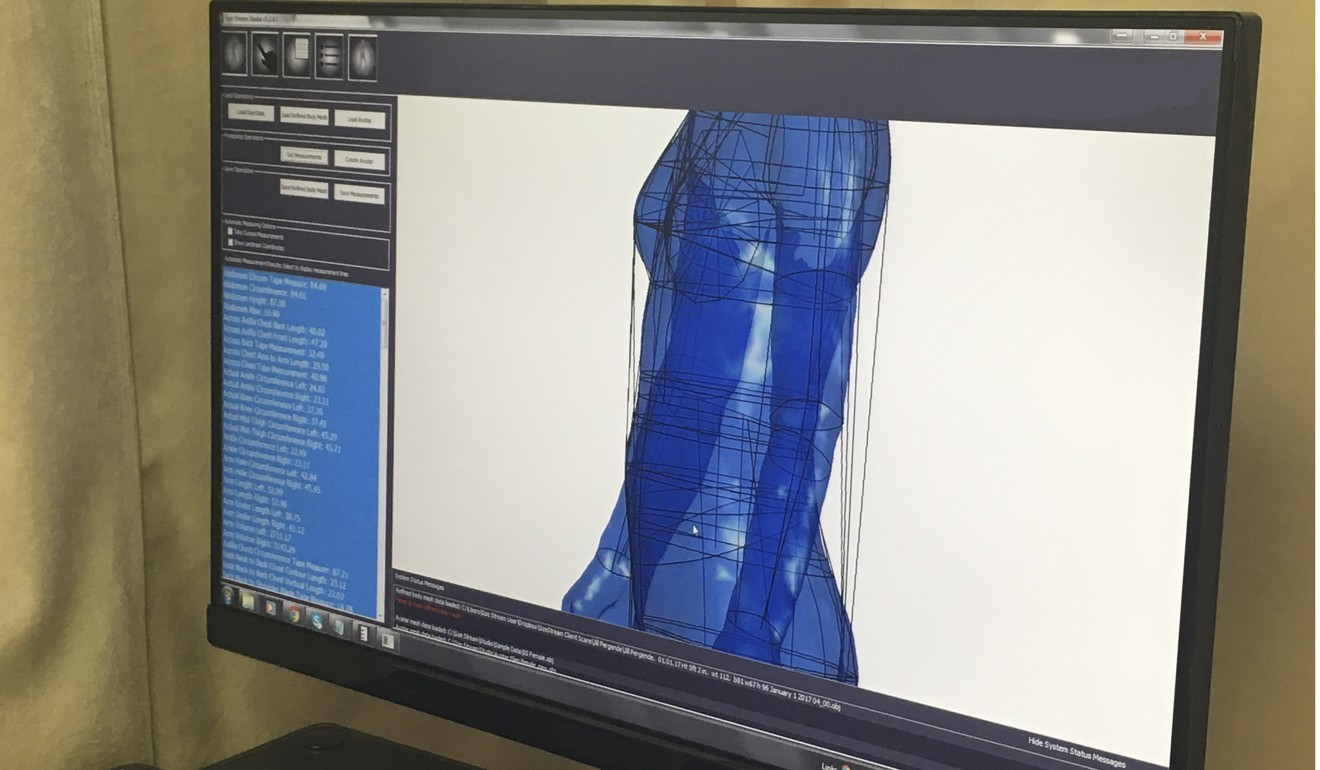

“I had an amazing pattern cutter, but he fell out with one of the sewers and took all the patterns with him,” she says. “I ended up finding some pattern-making software, but it wasn’t the best. It got me thinking about how we could capture accurate measurements, because doing it manually is never consistent. We got a 3D body scanner which really helped.”

Although the technology wasn’t exactly new (local brand Gay Giano also uses it), it got Chessis thinking about how to further improve the production process. After 18 months of research and development, she has just unveiled a system that she says will revolutionise custom-made clothing for women.

“We have been able to eliminate human error so that we can create patterns in an instant using an algorithm,” she says. “A person takes 20 minutes to an hour to make a pattern, but now we can do it instantly with absolutely no inaccuracies.

“Once the computer creates the pattern it goes straight to the printer. We are also working with our technology people to put software into the printer that allows us to print directly onto fabric rather than paper. This changes everything.”

The hard work has paid off. Chessis says the technology has reduced the production time for one item to one week, as against six to eight weeks previously. More than that, the fit is perfected instantly, thereby eliminating the need for further modifications. And, thanks to the efficiency of the system, she has been able to roll out an e-commerce site that offers the service to a global audience.

How Net-a-Porter invests in tech to future-proof luxury retail

“Right now we offer minimal customisation online – you can choose your neckline, trims, length or sleeve, but we are not doing colours or fabrics yet. If there’s demand, then we can add this,” she says. “Currently, we use a sizing predictor [online], as there’s no body scanner. It’s easy, as customers just need to input a few measurements and from those it predicts the size so we can create the most accurate pattern possible. Delivery is within one to two weeks.”

Looking ahead, Chessis is working with developers to find mobile body scanning software that will streamline the process even further.

“Eventually we will have showrooms in cities around the world, but I believe our future is online. It’s so easy and convenient, and if you can get the perfect fit, you can order anytime, anywhere and we can produce everything super quickly. That’s the future,” she says.