Smarter contact lenses and ‘invisible skin’: Chinese scientists give next-gen wearables a boost by making circuitry invisible

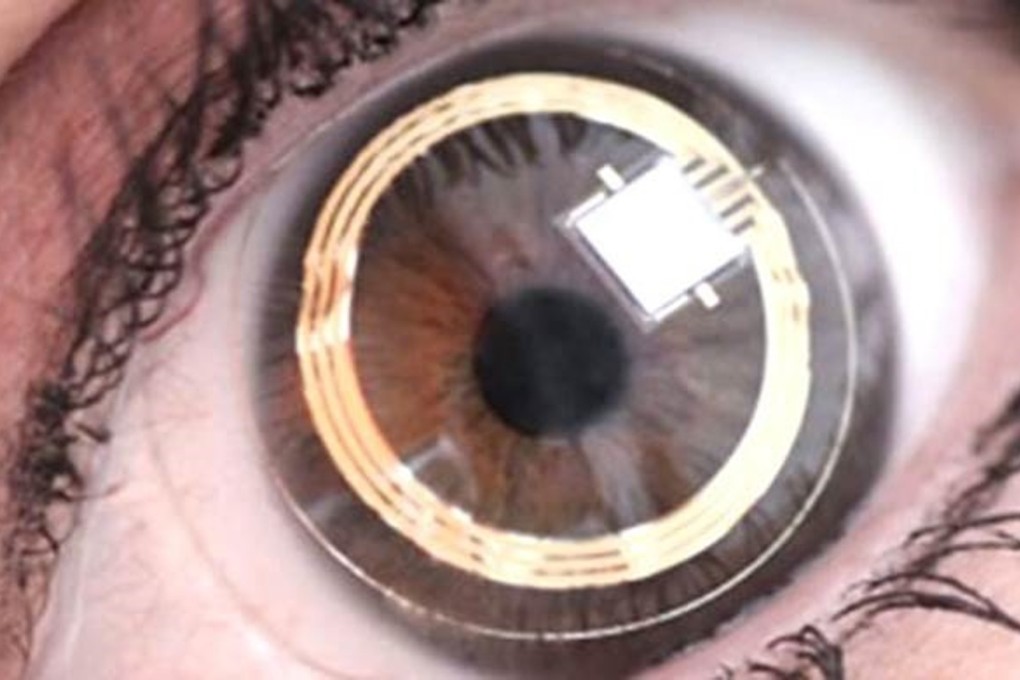

Chinese scientists have built an “invisible” circuit in a layer of material used to make contact lenses for the first time, a technological breakthrough that could spur the development of new wearable devices, according to their paper published in the latest issue of the journal Advanced Materials.

The research team led by Professor Song Yanlin created the electrical circuit inside dimethylsiloxane, a widely used silicon-based organic polymer that is used in contact lenses because of the optical clarity it yields as well as its safety features.

The circuit is invisible to the naked eye because it was formed by silver wires measuring just one micrometre in width, making it narrower than the diameter of a typical bacterial cell.

The technology provided “a new venue for … highly integrated and transparent electronics,” wrote Song and his colleagues from the Institute of Chemistry at the Chinese Academy of Sciences in Beijing.

Smart contact lenses with built-in electronic circuits are being developed in laboratories around the world as they can perform a range of jobs from creating virtual displays for gamers - part of the augmented reality trend - to measuring the level of glucose in human tears for patients with diabetes.

Technology giant Goggle launched a smart contact lens project of its own in 2014 to develop an “eye-mountable” device to monitor glucose levels.