UK-based Colorifix aims to bring environmentally friendly fabric-dyeing solution to China and Southeast Asia in 2025

- Biotech start-up will focus on markets in India and Sri Lanka next year, before making its move to China and Southeast Asia

- Production life-cycle using its solution can help reduce carbon emission by 31 per cent, water consumption by 77 per cent and chemical usage by 80 per cent

Colorifix, a finalist for Prince William’s Earthshot prize, aims to bring its environmentally friendly fabric-dyeing solution to markets in China and Southeast Asia in 2025 to help tackle pollution in the garment manufacturing industry.

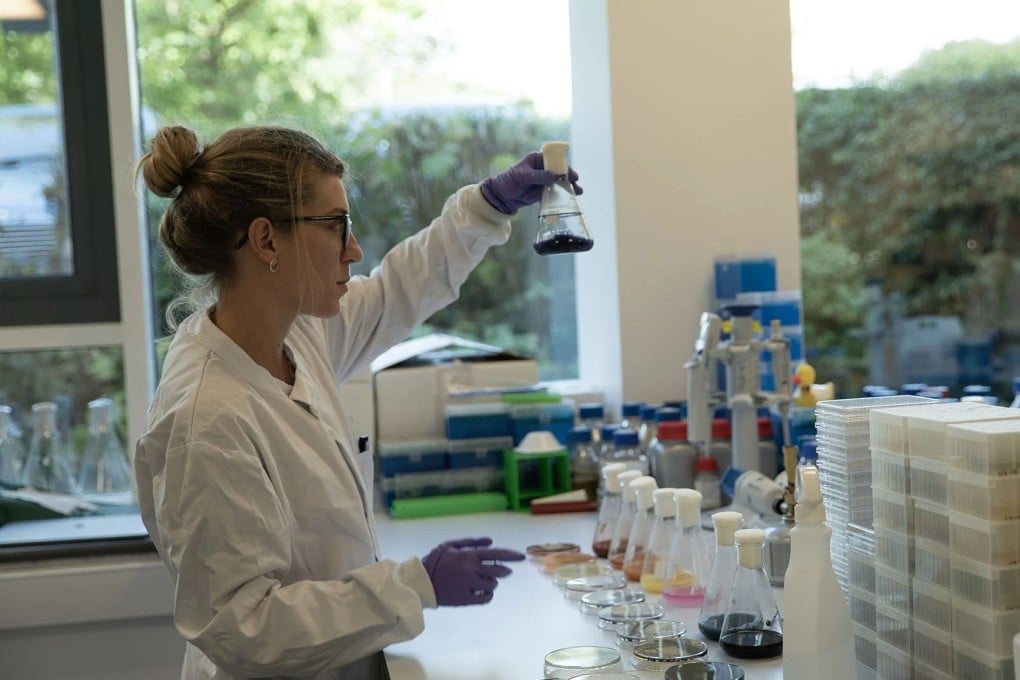

The biotech start-up uses DNA sequences from nature and microorganisms to create pigments that can be fixed onto fabrics in a way that significantly reduces water and chemical usage, as well as the carbon footprint in the dyeing process.

The UK firm will make its foray into the Asian markets from the first half of next year, starting with India, the world’s fifth-largest producer of textiles, and Sri Lanka, according to its chief operating officer Christopher Hunter. The firm is still in “very early stages” of establishing its presence in China, he added.

“China is a very important market for textiles,” Hunter said in a video interview on Tuesday. “We are aware that there are increasing environmental targets for the industry in China, which might in some way accelerate our entry. It won’t be before 2025.”