China’s C919 jet to be more home-grown with a domestically made engine, but how long will it take?

- Adviser to C919 passenger jet programme flags risks of China relying on foreign supplies of critical technology

- Several of the most technologically advanced components of China’s new passenger jet, including its engine, come from overseas

However, the engine still might not be ready for commercial use for several years, according to an adviser to the C919 programme.

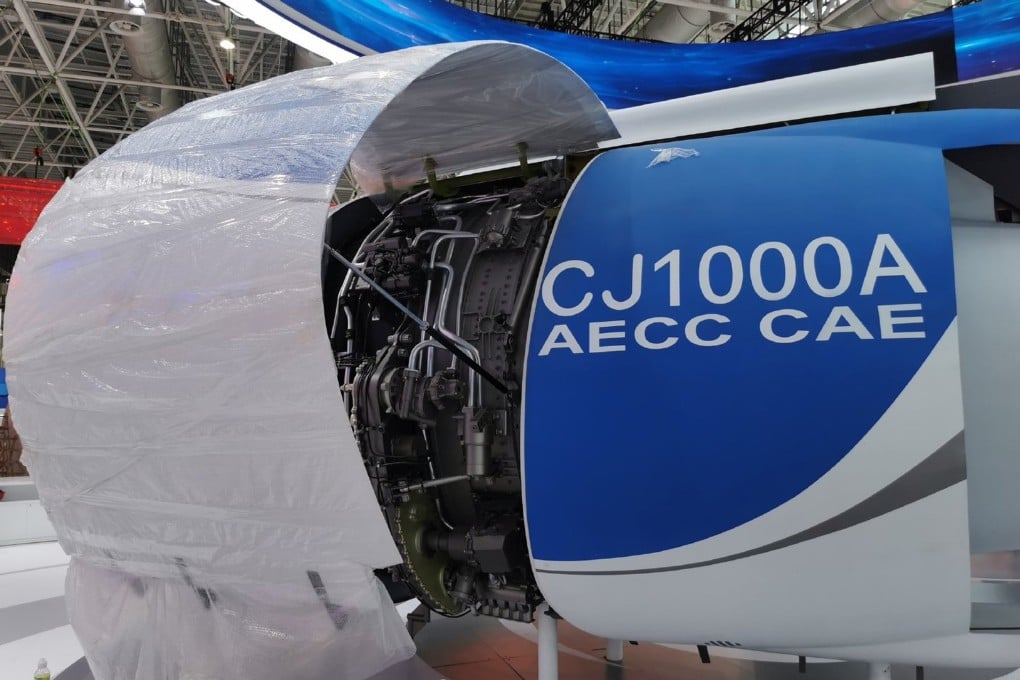

The state-owned Aero Engine Corporation of China (AECC) held a meeting on Sunday to outline plans to accelerate the airworthiness certification for its CJ-1000A engine, it said in a WeChat statement on Monday.

The meeting, which was attended by AECC’s senior management and the CJ-1000A’s development team, focused on defining the objectives and tasks for the certification and on making plans for research and development, as well as setting specific requirements for the team in charge of the certification.

The social media statement didn’t elaborate on details of the plan, nor did it give a timetable for when the CJ-1000A might be ready to be certified. The AECC did not immediately respond to faxed follow-up questions about the engine.

AECC’s engine update came less than two weeks after the single-aisle C919 finally received a “type certificate” from the Civil Aviation Administration of China (CAAC) after 14 years of development. The plane, made by the state-owned Commercial Aircraft Corporation of China (Comac), is designed to compete with Boeing’s 737 and Airbus’s A320.