US-led rare earths pact satisfies South Korea’s ‘definite need’ to cut China dependency

- South Korea joined the US-led Minerals Security Partnership earlier this month alongside the likes of Germany, France, Britain, Australia and Japan

- Australian Strategic Metals has also invested in South Korea to set up a joint venture to produce rare earth metals which will be turned into magnets for use by Hyundai

South Korea’s decision to join a US-led pact on mineral supply helps satisfy a “definite need” to cut dependency on China for key resources, including rare earths, analysts said.

Securing key resources has become a core task for major economies around the world, as minerals are a crucial element incorporated into cutting-edge technologies, green energy and national defence industries.

Countries have traditionally relied on China as it not only holds the largest amount of rare earth reserves, but it also is the world’s biggest producer.

“Korea is more dependent on China [for supply of rare earths] because of proximity and because of the structure of trade between the countries where intermediate goods account for large part,” Kim Kyoung-hoon, senior researcher at the Korea International Trade Association’s (KITA) Global Value Chain Research Task Force, said.

South Korea has its own rare earth reserves, but does not possess the relevant production capabilities – although in recent years it has moved to produce rare earth magnets.

A first step to establish an integrated supply chain was taken when Australian Strategic Metals invested in South Korea to set up a joint venture with its subsidiary, KSM, to produce rare earth metals with raw materials sourced from Australia.

KSM completed setting up its production plant in Ochang, North Chungcheong province, last month and the company plans to produce 5,000 to 10,000 tonnes of rare earth metals on an annual basis.

While Korea’s production of rare earth metal and magnets is in its very early stages, it is significant that it has set up a domestic base for production

The Korean-produced rare earth metals will then be turned into magnets by an intermediary for use by Hyundai Mobis, the parts and services arm of the South Korean multinational automotive manufacturer.

“There is definitely a need for Korea to diversify sources of supply. While Korea’s production of rare earth metal and magnets is in its very early stages, it is significant that it has set up a domestic base for production,” added Kim.

US allies in Europe, such as Germany, France and Britain, as well as others in the Asia-Pacific region, including Australia, Japan, have also signed up to the Minerals Security Partnership.

“Demand for critical minerals, which are essential for clean energy and other technologies, is projected to expand significantly in the coming decades,” the US Department of State said earlier this month.

It also said members “are committed to building robust, responsible critical mineral supply chains to support economic prosperity and climate objectives”.

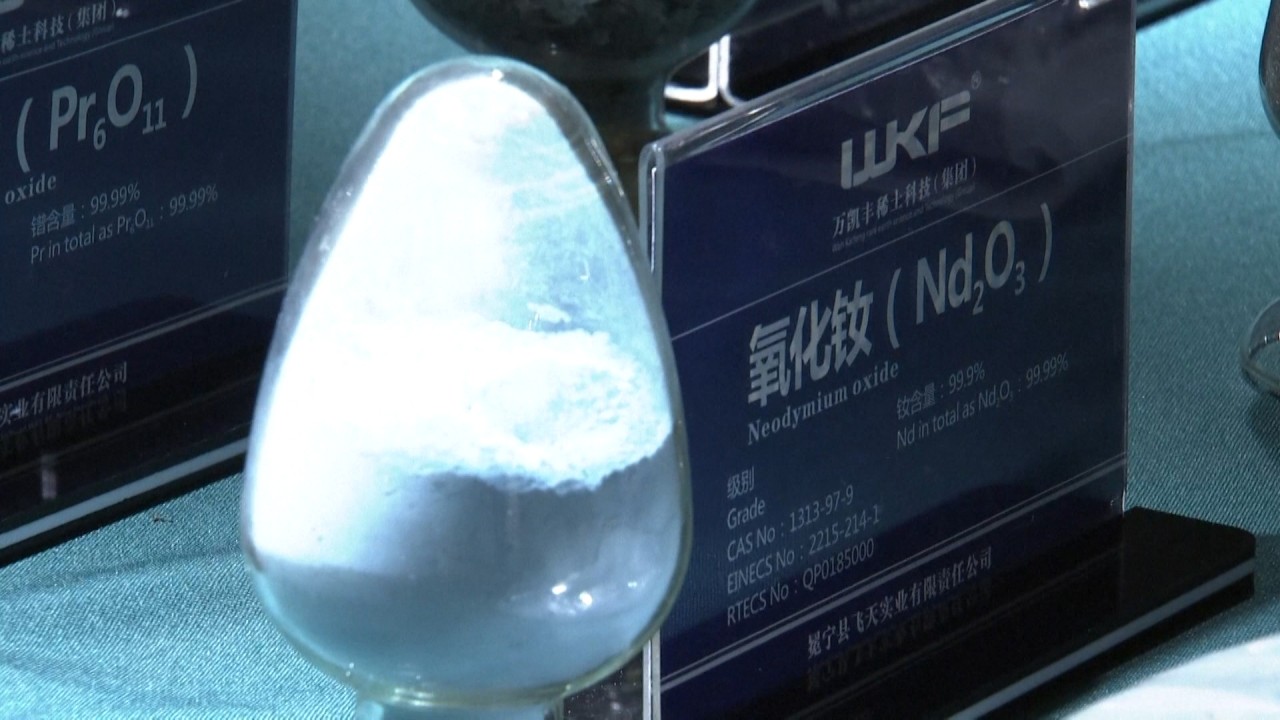

Rare earths are a group of 17 chemically similar elements composed of scandium, yttrium, and the lanthanides that are abundant in nature, but difficult and dirty to extract.

China accounted for 58.9 per cent of South Korea’s rare earth imports in terms of volume in 2020, according to the KITA.

“Rare earths are becoming increasingly important as industries covering electronics, chips and automobiles become more advanced,” said Lee Jay-yoon, the director of the materials industry and sustainability division at Korea Institute for Industrial Economics & Trade.

Korea has faced the need to utilise diplomatic relations and boost its network when it comes to economic security

He referred to the experience in 2019 after Japan placed restrictions on exports of its hi-tech materials and parts, which South Korea was highly dependent on.

“Korea has faced the need to utilise diplomatic relations and boost its network when it comes to economic security,” Lee added.

China began tapping into its rare earth reserves in the 1950s, taking advantage of a lack of environmental regulations to dominate the global market.

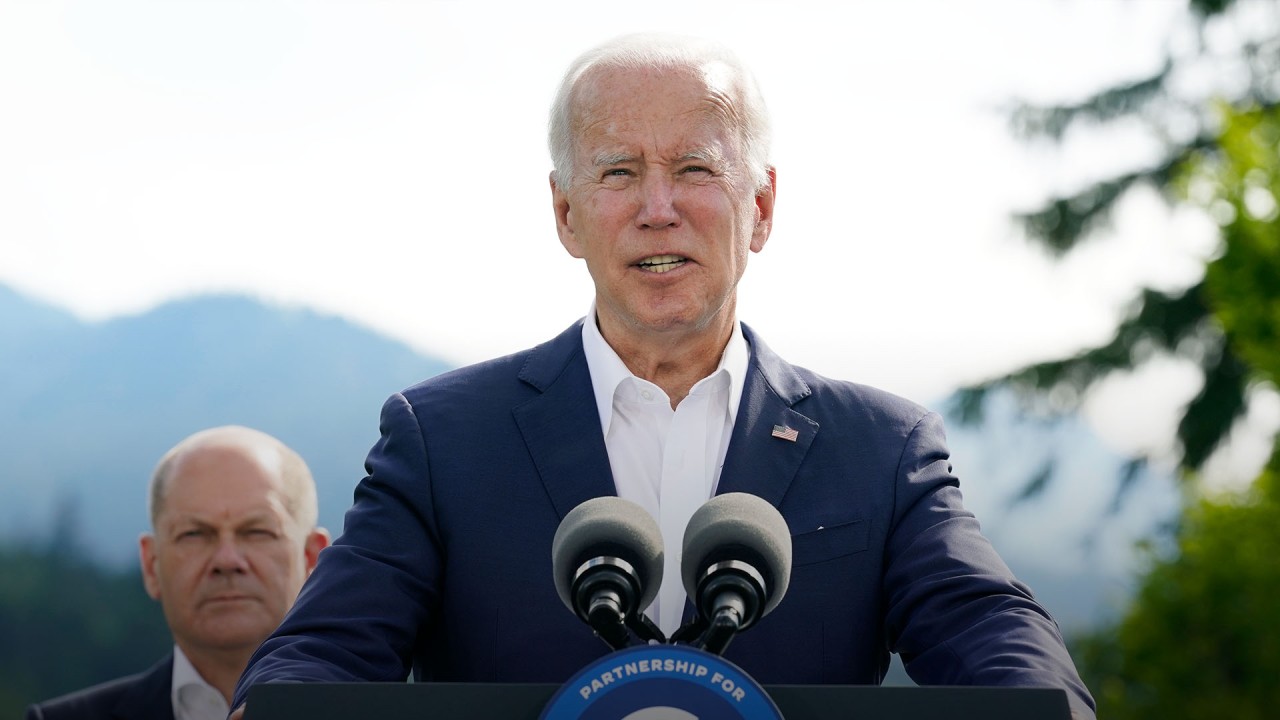

Biden gives mining operations a boost as US looks to buck reliance on China

The difficult and costly process of extracting resources, as well as the environmental pollution involved, have served as substantial barriers for other nations to produce rare earths.

China holds 35.2 per cent of global rare earth reserves – equivalent to 12.5 billion tonnes – according to data from the US Geological Survey. It is followed by Vietnam with 17.6 per cent and Brazil and Russia each with 16.8 per cent each.

The world’s No. 2 economy produced 140,000 tonnes of rare earths in 2020 compared to just 39,000 tonnes from the US.

Myanmar produced 31,000 tonnes in 2020, with Australia fourth with 21,000 tonnes.

China’s portion of global rare earth production peaked at over 80 per cent after 2000 as economies opted to import resources that were cheaper than producing their own, but the percentage has fallen to around 60 to 70 per cent.

This is attributed to countries recognising the importance of rare earths given their use in cutting-edge industries, and instead turning to utilise their own resources.

In China, 42 per cent of rare earths were used to manufacture permanent magnets that are used in electric vehicles.

Some global carmakers, including Nissan and BMW, have opted to reduce the use of rare earth magnets in their electric vehicles given the risks associated with supply despite being more efficient.

GM has also stated that it will source and produce rare earth electric vehicle magnets in the US.

Traded rare earths are categorised into rare earth metals and rare earth compounds.

China’s new rare earth merger hands it ‘trump card’ against US

The growth is attributed to increasing demand as the eco-friendly and cutting-edge technology industries develop and as major economies seek to stock up on key materials over concerns of supply chain disruptions.

In 2021, the largest importers of China’s rare earth metals were Japan, the Netherlands, Italy, India, the US, Canada, Brazil and South Korea.

China, meanwhile, accounts for 88 per cent of South Korea’s rare earth magnet imports by value.