The Corkscrew | What fine wine and good vinegar have in common

And you can even try making the latter at home

The discovery of the winemaking process apparently coincided with that of the vinegar-making process, which is hardly surprising.

One of the most important steps in winemaking is limiting exposure of the developing wine to air. Although air is essential to the process while yeast molecules ferment the sugar in grapes, after this step (called alcoholic fermentation), exposure to air must be controlled, to prevent the fermented juice from turning sour through the development of acetic acid. Microbes in the air metabolise alcohol in the fermented juice, leaving behind just the acids and producing what the French named vin aigre, or “sour wine”.

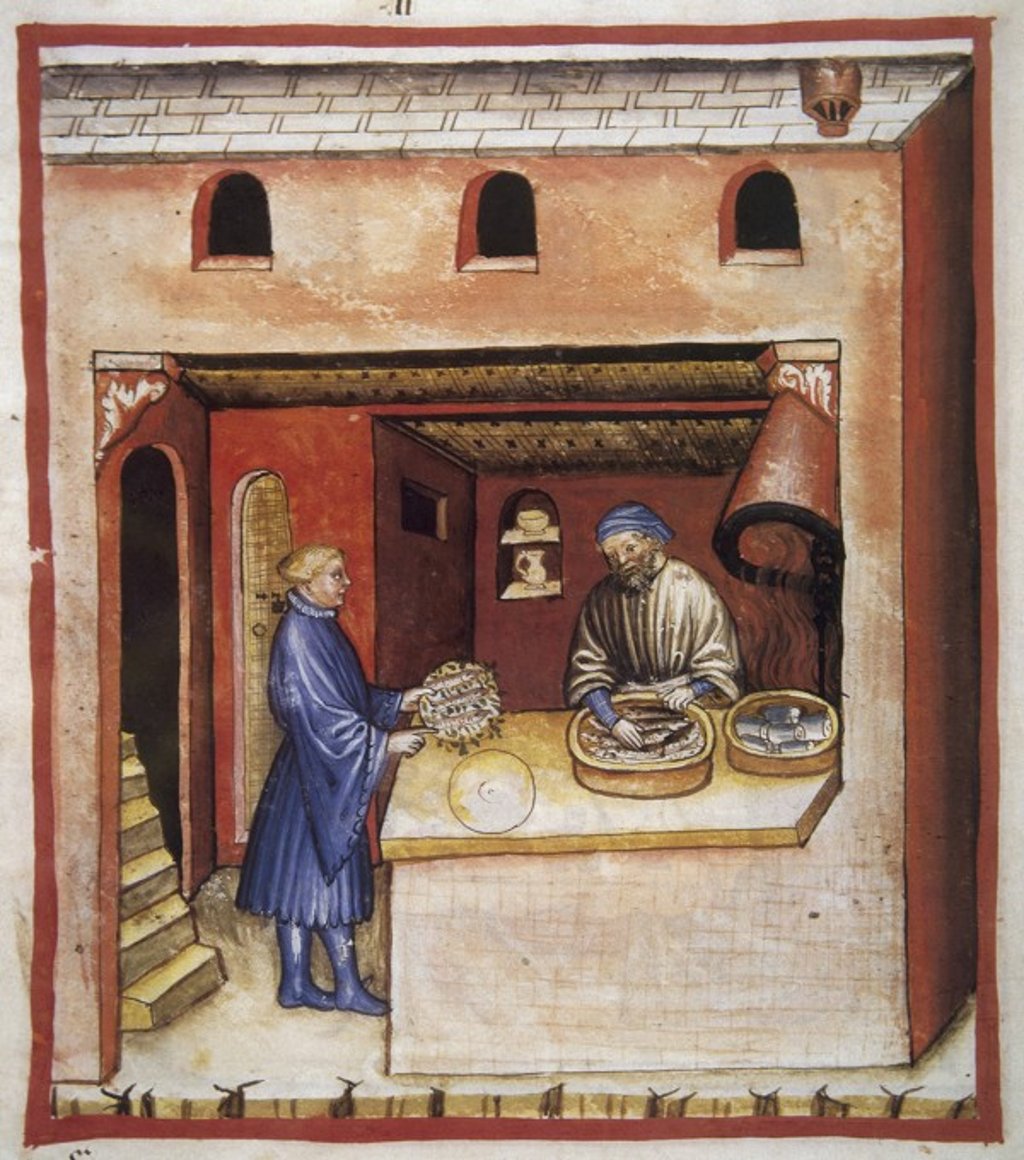

Until the 17th century, making vinegar was a lengthy process. Partially filled containers of wine or other alcoholic drinks of inferior quality were left open, exposing the contents to air and turning the liquid sour.

The first innovation in vinegar-making was developed by the French, the vinegar-to-be periodically poured over grapevine twigs to increase aeration. In the 18th century, a Dutch scientist came up with the idea of continuously trickling wine to speed up the process. Then came Louis Pasteur, who discovered which microbes worked best to make vinegar – they were dubbed Acetobacter pasteurianus (after the man himself), Acetobacter aceti and Gluconobacter.