Hermès’ silk scarf: how the timeless beauty is made

What’s the secret behind Hermes’ silk scarves? We uncover little-known facts about the material and the design

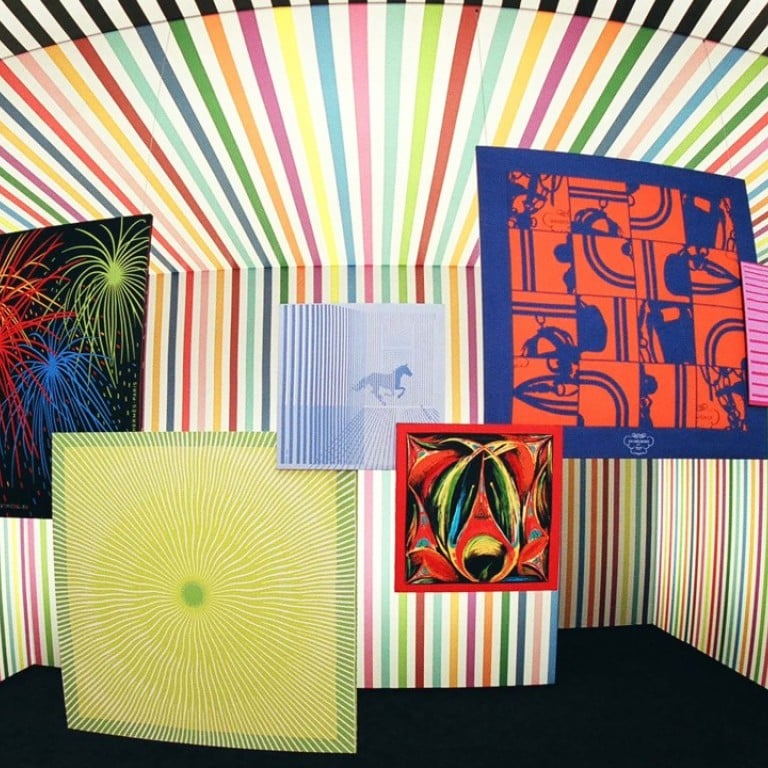

Since the very first silk square was produced in 1937, Hermès’ 90cm x 90cm carré has become an iconic item and a work of art, with more than 1,500 versions created up till now.

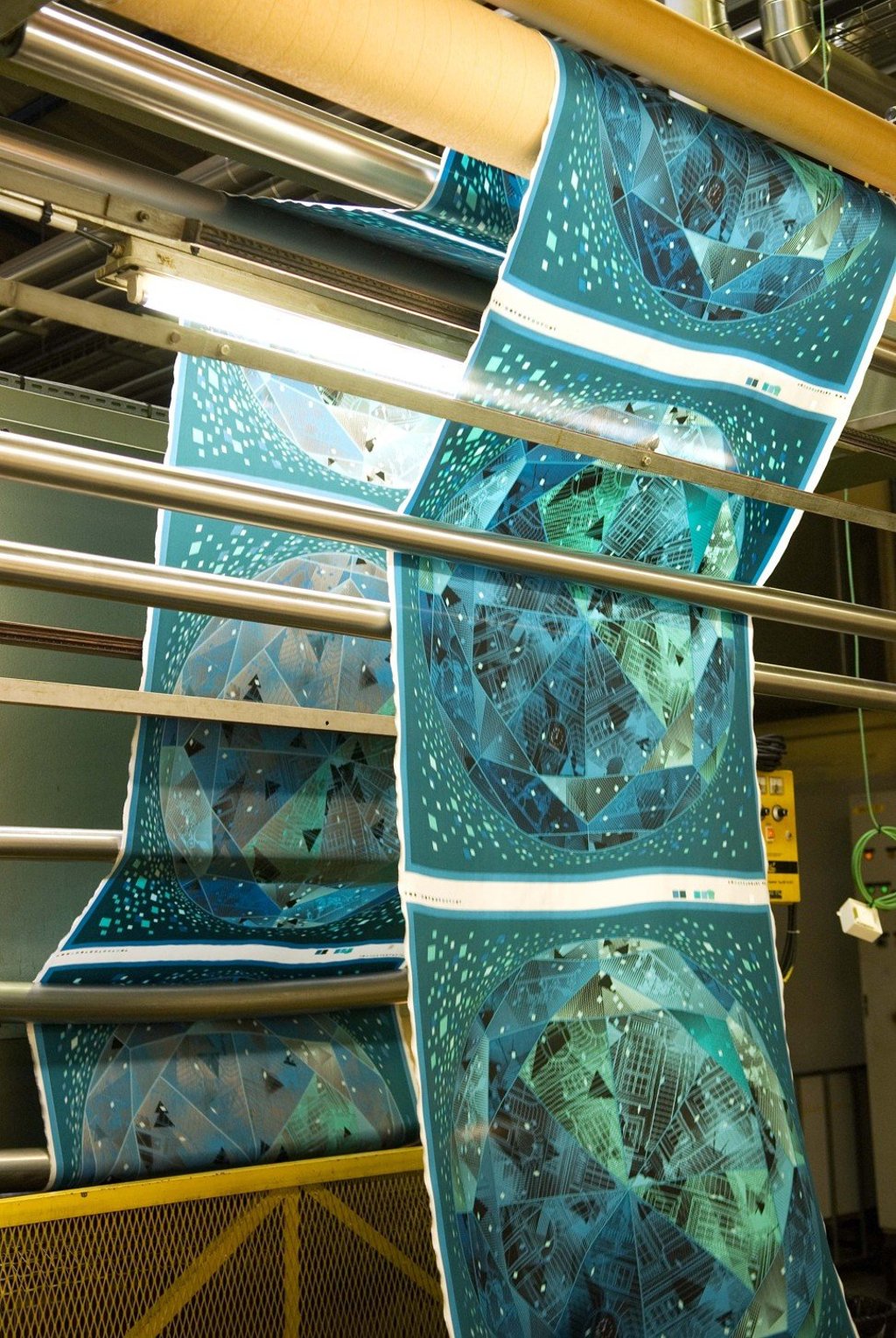

Each season, more than 10 new designs are transposed onto silk from paper. The new design, originally a life-size mock-up painted by hand on card (90cm x 90cm), is first separated into as many films according to the different colours in the engraving workshop. For a design featuring 30 colours, it requires between 400 and 600 hours of engraving. For complex designs such as the well-received Les Jardins d’Andalousie, 1,500 to 2,000 hours of engraving is needed.

Before the carré is delivered to customers, it will undergo a final operation – “roulotté”. Seamstresses using silk thread of an identical colour to that of the border create a unique rolled hem on the edges of the scarf.