Curations: Omega’s historic passion for precision set the stage for its Master Chronometer certification

- The Swiss luxury watchmaker made its name in the 19th century, revolutionising the industry with a calibre that set a new standard for manufacturing

- Omega established its own testing process in 2015 to account for modern watch features such as resistance to magnetic fields made by hi-tech devices

Omega’s long history of groundbreaking precision watchmaking started with a 23-year-old entrepreneur who worked from home. In 1848 in the Swiss village of La Chaux-de-Fonds, a young watchmaker named Louis Brandt opened a workshop in his family villa to assemble key-wound pocket watches.

While Brandt quickly became known across Europe for creating high-quality precision timepieces, he aimed to take watchmaking to another level. He had a vision to devise a watch mechanism that would provide the most accurate time measurements possible.

Brandt’s passion for precision was passed down to his sons Louis-Paul and César, who took over the business after their father’s death in 1879. Together, they produced several new innovations in watchmaking, leading up to the invention of the 19-ligne Omega calibre in 1894.

This movement made of interchangeable parts revolutionised the industry, as it set a new standard for the mass production of watches. The Brandt brothers named the calibre after Omega, the last letter in the Greek alphabet, to signify its status as the crowning achievement in watchmaking at the time.

The success of the Omega calibre led the Brandts to adopt the name for their company, and a new watchmaking brand was born.

During the 20th century, the Swiss luxury watchmaker built upon its reputation for precision. In addition to manufacturing watches and winning observatory trials for accuracy, Omega got involved in sports timing, and in 1932 was selected as the official timekeeper of the Olympic Games in Los Angeles. It provided timing for all the Olympic events that year using one watchmaker and 30 chronographs.

Since then, Omega has literally stood the test of time, serving as the official timekeeper for nearly all the Olympic Games that have followed. Over the decades, the brand introduced revolutionary timing technologies that have improved sports timekeeping from one-tenth of a second in 1932 to one-thousandth of a second, as seen at athletic events today.

As Omega approached the next century, the quest for greater precision continued to prevail. In 1999, it unveiled the Co-Axial escapement, the first new practical watch escapement to be developed in 250 years. Invented by George Daniels – a British horologist known for building watches entirely by hand – the escapement reduces friction between its surfaces, allowing for improved reliability.

The escapement has since been featured in several innovative Omega calibres, including the anti-magnetic Co-Axial 8508, which was introduced in 2013 in the Seamaster Aqua Terra watch. Designed in response to the growing use of wireless devices, the movement is resistant to magnetic fields of 15,000 gauss, compared to previous anti-magnetic watches that could only resist levels of around 1,000 gauss.

Omega and other watchmakers based in Switzerland get their creations certified by Contrôle Officiel Suisse des Chronomètres (COSC), the country’s official chronometer testing institute that verifies the accuracy of watch movements. However, Omega realised that its new innovations like the Co-Axial 8508 operated beyond the COSC’s testing parameters.

The brand saw an opportunity to establish a new, cutting-edge certification process that would take other functional aspects of a watch into account, such as magnetic resistance.

This marked the advent of Omega’s Master Chronometer testing in 2015, which the watchmaker now applies to most of its timepieces in addition to COSC certification testing.

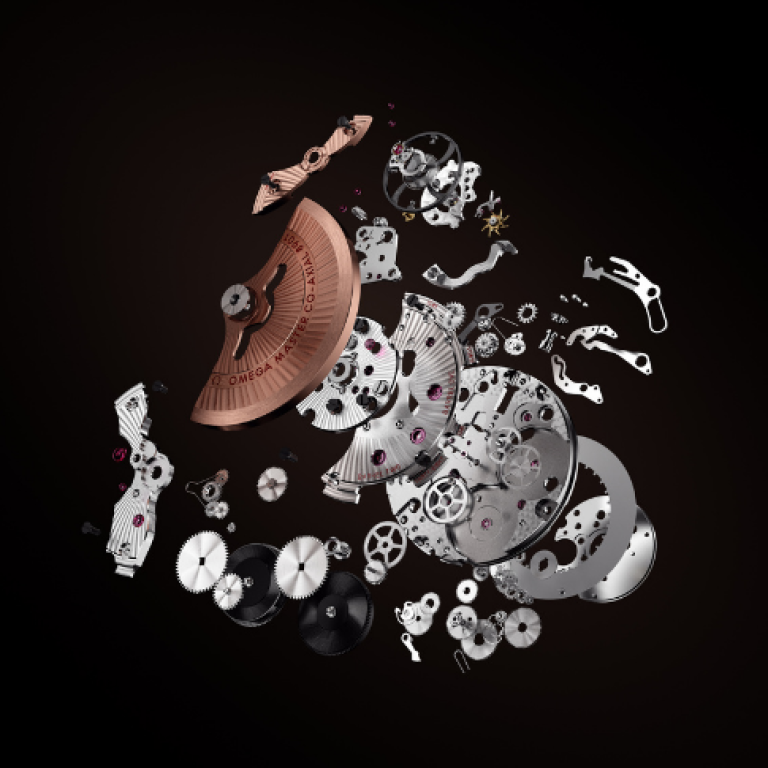

Omega subjects both its watch movements and completed timepieces to Master Chronometer testing, which focus on the performance of a watch through a range of conditions related to everyday wear. Eight tests are conducted over 10 days – including ones for water resistance, temperature changes and exposure to magnetic fields – all under strict accuracy criteria that ensures every watch is performing at peak precision.

Magnetic resistance, in particular, is essential to a watch keeping accurate time. People are constantly surrounded by magnetic fields of varying strengths emitted by the electronic gadgets they use, such as a hairdryer (400 gauss) or a laptop (1,200 gauss). These can disrupt the functions of a watch’s movement and compromise its accuracy over time. Master Chronometer certification ensures that Omega timepieces can resist magnetic fields as powerful as 15,000 gauss and continue to maintain their precision.

Every Master Chronometer timepiece comes with a red card bearing a certificate that verifies it has passed all eight tests under the official approval of the Swiss Federal Institute of Metrology (METAS), a government authority on precise measurements. Watch owners can check how their timepieces fared in specific quality, endurance and accuracy tests by entering the certificate number on the Omega website.

This red card accompanies an ever-growing range of Master Chronometer-certified watches. Some of the latest Omega models to receive the certification include the Seamaster Aqua Terra Worldtimer and the updated Seamaster Aqua Terra with blue and green dials.

With the METAS-approved Master Chronometer certification process, Omega has once again set a new standard to transform the watchmaking industry – carrying on a mission that began more than 170 years ago.