Rolls-Royce predicts it will create tailor-made cars for the rich and famous

It may soon be possible for the wealthy to have a one-off vehicle produced for them according to their own personal specifications

Bespoke services are enjoying boom times, and the fantasy of a one-off luxury car designed just for you could soon become a reality. The idea of a completely individualised car has, in a business that requires standardised tooling and economies of scale to work well, remained a dream. Yet, Rolls-Royce now says it could be around the corner – or at least here within the next couple of decades.

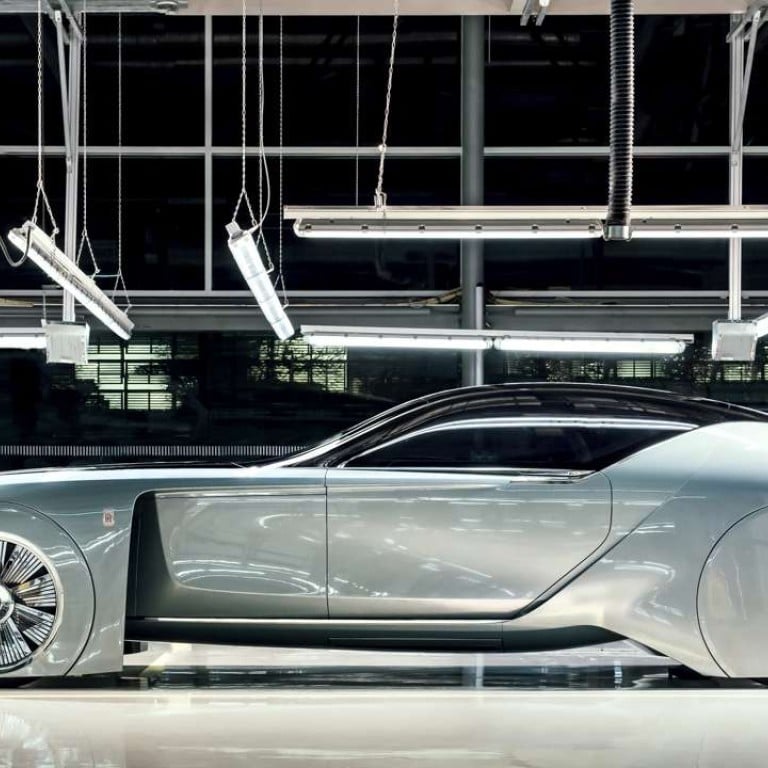

That’s the contention of Giles Taylor, Rolls-Royce’s head of design, whose latest project, the Rolls-Royce 103EX, is a vision of where the company’s car making will be in years to come. Most striking of all, among the many ideas it includes, is the notion that a customer will, effectively, be able to not just have the interior and finishing to his personal taste – as services the likes of Bentley’s Mulliner and BMW’s Individual Manufaktur departments already offer – but the actual bodywork too.

“Fundamental to the idea of the 103EX is that it will allow the possibility of a fully personalised car, such that nobody’s Rolls-Royce would look like any other – each would look unique, and not just at the level of, for instance, the colour of the upholstery,” Taylor explains.

The idea of bespoke cars has always posed the ultimate headache for the used car trade. According to one study, by automotive analysts CAP, the car industry is seeing a proliferation of new models as it attempts to fill ever more niche market gaps. But that’s not the real problem. It’s the explosion in options within in each model. Indeed, CAP reports a 187 per cent increase in option “packs” over just a three-year period. That makes comparing cars bewildering. Imagine the confusion on the forecourt.

Legalities will also become more complicated. “The possibility of a fully bespoke car will exist but the legislative changes in the automotive industry will make it tricky,” argues Uday Senapati, the head of technical operations at Bentley’s Mulliner operations, “and regulations are only likely to get more stringent, with the advent of autonomous cars, for example.” But it’s the way we want to shop these days: whether it be demand for distinction amid globalisation’s homogenous products, a means of filtering huge consumer choice or – more psychologically – to expressing our individuality, as shoppers we’re looking for the things we buy to be as unique as possible. What was once only typical of the top of the market, is now a mass-market phenomenon – everything from jeans to sneakers can now be easily customised prepurchase.

Taylor concedes that he’s taking a bet that the technology will be available to allow this to happen – “we can only guess when” – but is extrapolating from tech already here and improving all the time.

3D printing, for instance, is, he notes, already being used to make parts for Formula One racing cars. Red Bull and Lotus are among the teams known to use 3D printing in the manufacture of parts for test cars, with the Caterham team having made up to 900 parts a month and seeing them successfully survive the extreme forces of Formula One.

Rapid prototyping, which decreases development time and allows corrections to be made early (and inexpensively) in the process, will also play a part. Such technologies would, says Taylor, make realistic the kind of car body parts that would be prohibitively expensive if possible to make using conventional methods.