Advertisement

Researchers shed light on smart tech that made Chinese flag the first on Mars

- Lightweight polymer allows national banner to ‘fly with the wind’ on red planet and is likely to be used in interplanetary travel and aerospace engineering

- Patented materials could push China ahead in space race as rival Nasa relies on heavier, more expensive components

Reading Time:4 minutes

Why you can trust SCMP

14

Chinese researchers for the first time shared details about the technology that made China the first country to put its national flag on Mars, forcing former US president Donald Trump to eat his words.

The US placed its flag on the moon more than 50 years ago and intends to do it again on the red planet. “The United States will be the first nation to plant our beautiful American flag on planet Mars,” Trump said in 2019.

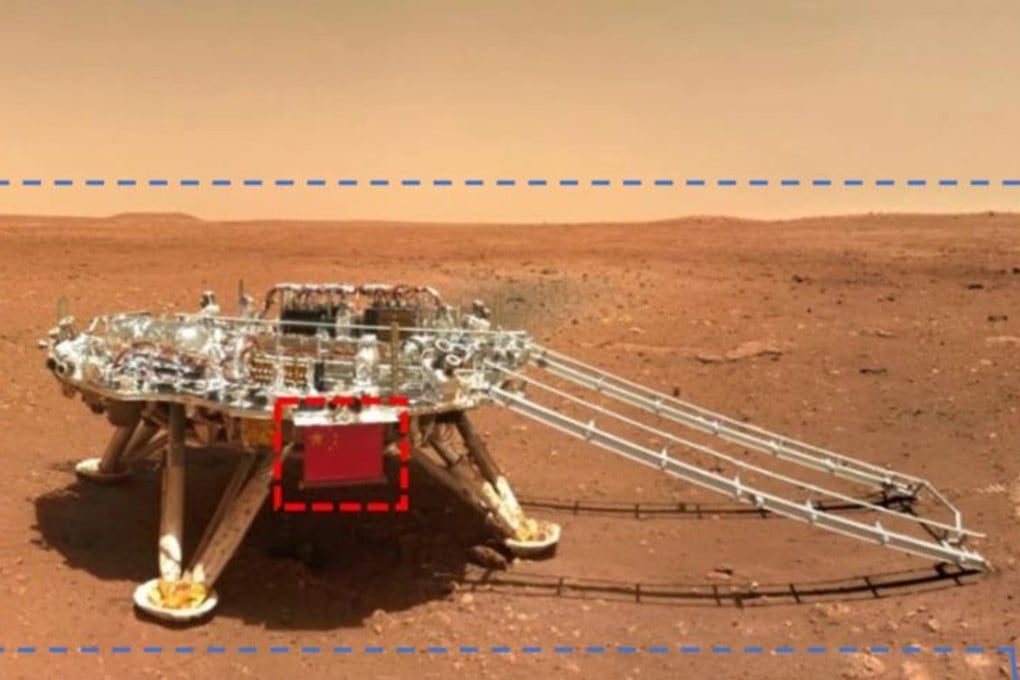

But on May 15, 2021, after an interplanetary journey of nearly 500 million km (300 million miles) lasting over 300 days, China’s Tianwen spacecraft unfurled a Chinese flag on Mars – the first national banner placed on the planet. The red flag with five yellow stars, made of a cloth-like smart material, moved gently in the Martian breeze.

Advertisement

In a paper published on Monday in the peer-reviewed Advances in Mechanics, Chinese researchers unveiled details of the new material, which is expected to be used in interplanetary travel, asteroid exploration and other space infrastructure projects.

A robotic device that can hold and unfold a flag typically requires several mechanical components. These metallic parts are heavy and can increase the cost and risk of a mission significantly.

Only a low-cost, lightweight and reliable technology would make it possible for the “five-star red flag to fly with the wind on Mars”, the researchers said.

Advertisement

Select Voice

Select Speed

1.00x