Chinese scientists say their silkworms beat spider fibre for strength

- New process creates silk that is 70 per cent tougher than the stronger-than-steel version spun by spiders, researchers say

- It can be used for clothing, surgical stitches and other medical devices, according to team in China

Chinese scientists say they have developed a way to manually spin silk from silkworms to make it 70 per cent tougher than the strongest silk spun by spiders.

The researchers said their “artificial superstrong silkworm silk” is safe and durable for use in surgical stitches, scaffolds for bone and tendon regeneration, mesh or films for delivering medicines, as well as for producing lightweight clothing.

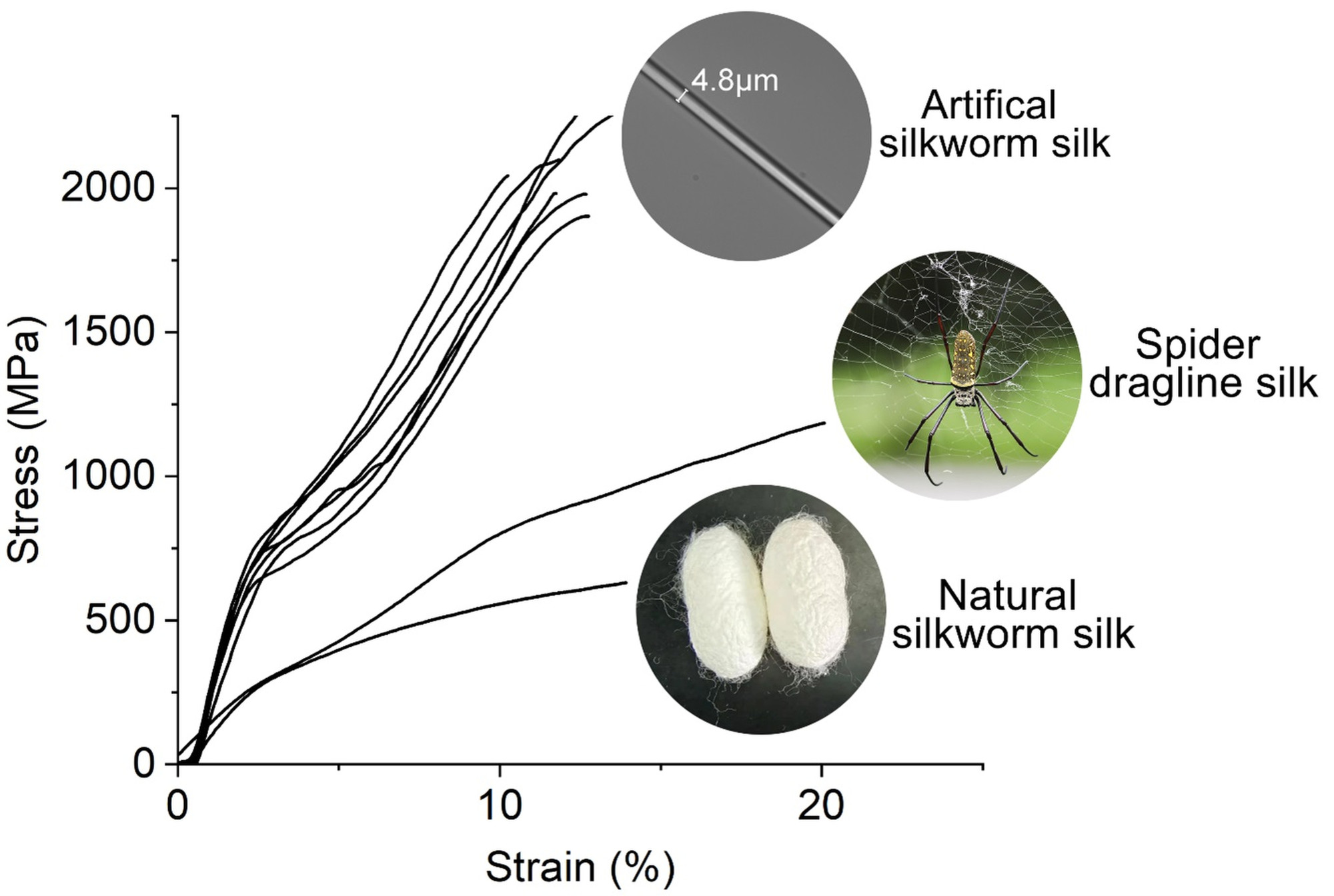

China has a long history of farming silkworms for textile production. Their silk is much weaker than spider silk, especially dragline silk, which the arachnids use to build webs and as a lifeline when they hang in mid-air.

Spider silk is five times stronger than steel. But unlike silkworms, spiders are too aggressive and territorial to be farmed, according to the research team.

Some scientists have genetically engineered silkworms with spider DNA, but this is expensive and difficult to scale.

In the new study, the Chinese team used common silkworms, which are easily obtained from farms, to create silk fibres that surpass natural spider silks in strength and stiffness.

Natural protein-based silks spun by spiders, silkworms, other insects and mussels “have long attracted our interest for thousands of years owing to their extraordinary physical properties, excellent biocompatibility and long-term biodegradability,” the researchers wrote in an article published on Thursday in the peer-reviewed journal Matter.

“The deliverable from this study reverses the previous perception that silkworm silk cannot compete with spider silks on mechanical performance.”

“The method developed here thereby opens a promising door to produce profitable, high-performance silk-based materials on a large scale,” said the researchers from Tianjin University and Ningxia Medical University.

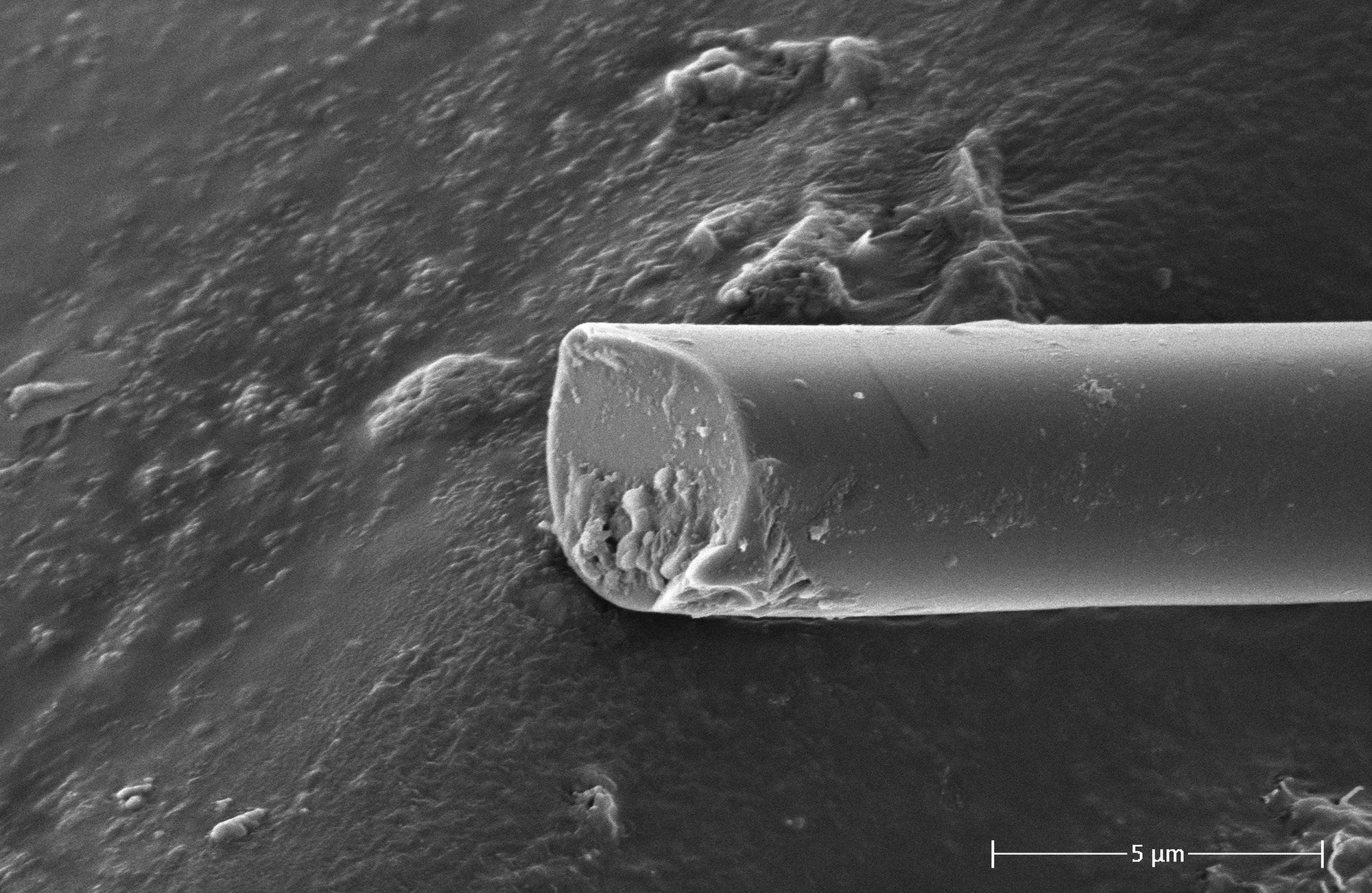

The team first boiled silk from the common domesticated silkworm Bombyx mori in a bath of chemicals to dissolve the glue around the core fibre, which interferes with spinning, and to minimise the degradation of silk proteins.

They then solidified the silk in a bath of zinc, iron and sugars. The manually spun and drawn silk was thinner than the original silkworm silk and similar to spider silk in size.

Senior author Lin Zhi, a biochemist at Tianjin University, said artificial silkworm silk is much cheaper to produce on an industrial scale than lab-made spider silk thanks to large-scale breeding of silkworms.

“Our team is currently developing the second generation of high-performance silk and optimising the automated spinning process to improve yield and reduce production costs,” Lin said.

“We are seeking funds to accelerate the development of different types of new silk-based biomaterials and expect to launch high-strength and eco-friendly silk-based textile products in the next few years,” he said.