How China’s ‘fancy tool’ cut chip defects by 99% for near-perfect lithography

Cryo-ET process pinpoints source of manufacturing flaws to achieve unprecedented clarity and a pathway to major industry cost cuts

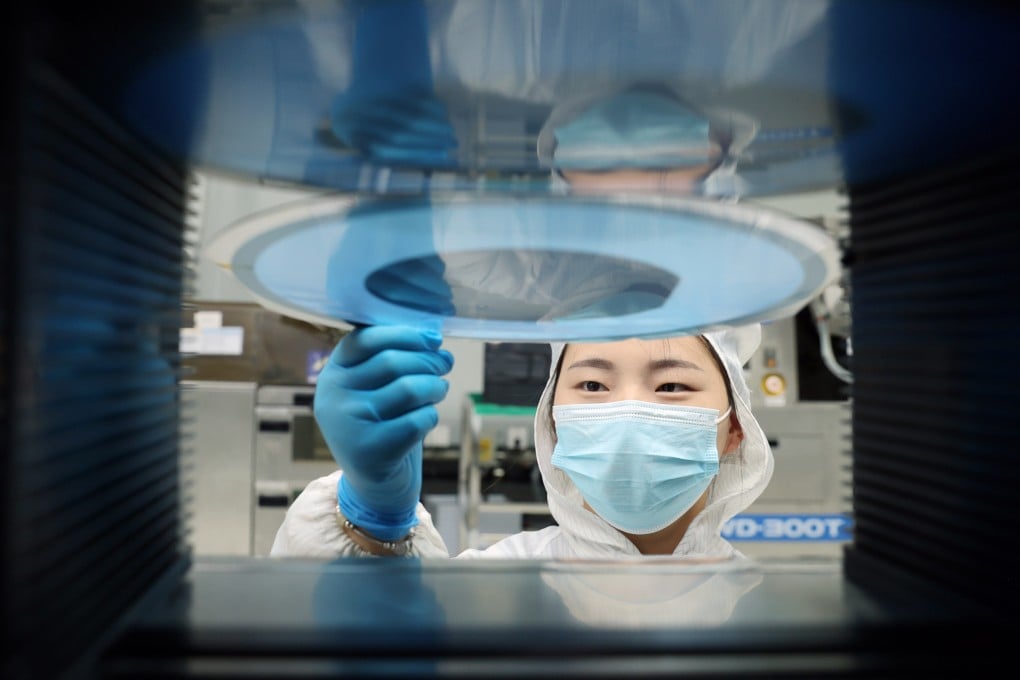

The researchers achieved unprecedented clarity by using cryo-electron tomography (cryo-ET) to pinpoint, for the first time, the minute sources of common manufacturing flaws.

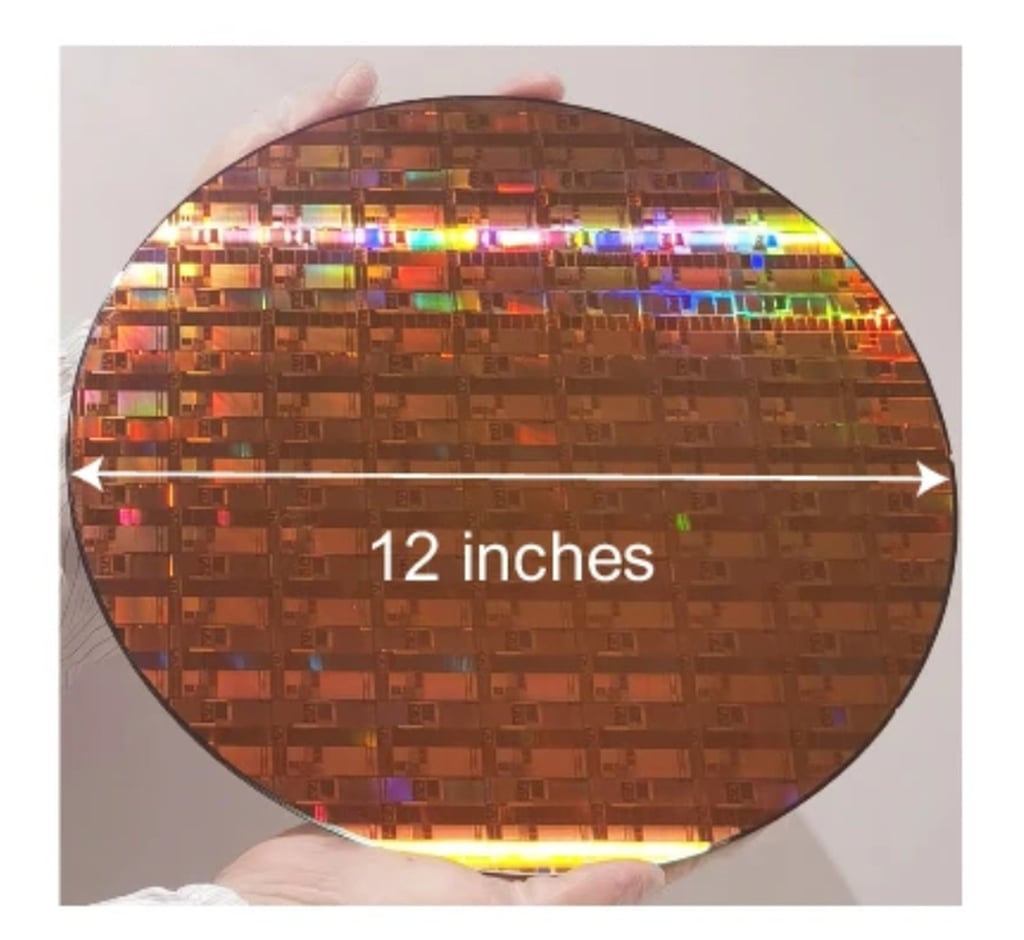

“The team has proposed a solution compatible with existing semiconductor production lines,” Peng said in an interview with Beijing-based Science and Technology Daily published on Monday. “It can reduce lithography defects on 12-inch (30cm) wafers by 99 per cent,” he added, indicating substantial cost benefits to the market.

Lithography is one of the most critical steps in chip manufacturing. “It can be understood as ‘printing circuits’ onto semiconductor wafers such as silicon,” Peng said. “Essentially, an ultra-precise ‘projector’ shrinks and transfers pre-designed circuit patterns onto a special film coating the wafer, which is then developed and fixed.”