Advertisement

The Polytechnic University lab 3D printing face shields for coronavirus-battling Hong Kong hospital workers

- Technicians hand over 10,000 of the coverings to Hospital Authority

- There are plans to make up to 30,000 per day by the end of March, in conjunction with local manufacturers

Reading Time:2 minutes

Why you can trust SCMP

A Hong Kong university is using new technology to spearhead efforts to send thousands of medical face shields to the city’s hospital workers as they battle to contain the coronavirus outbreak.

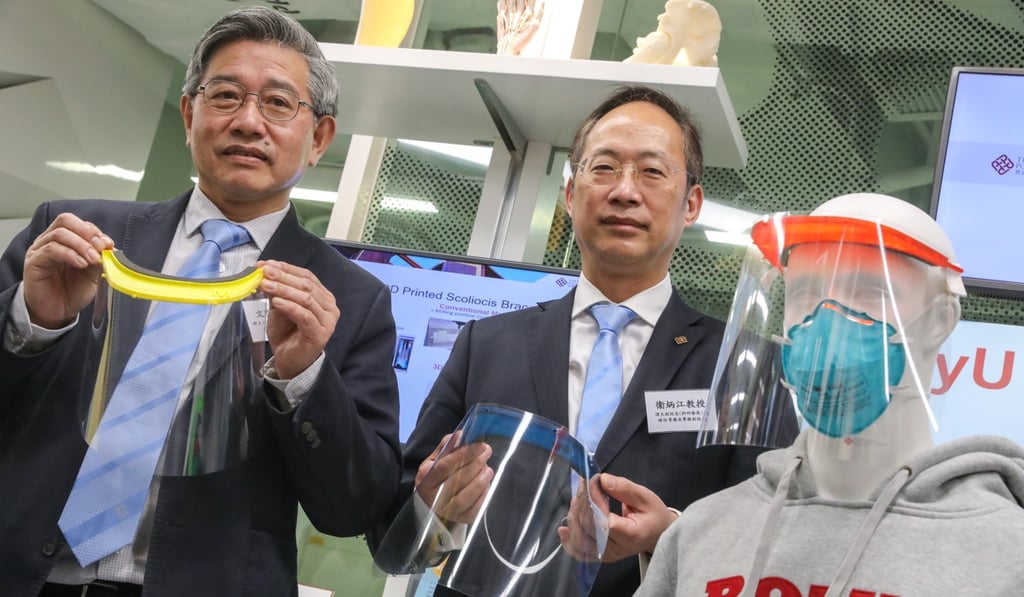

Polytechnic University’s 3D printing lab designed and helped produce the transparent coverings, which doctors and nurses can wear to protect themselves against bodily fluids, which could carry infection, lab leaders said on Monday.

Working with local manufacturers, it will deliver 10,000 face shields to the Hospital Authority on Tuesday, with production of up to 30,000 per day predicted by the end of March.

Advertisement

“PolyU is doing technology transfer to the industry, and for industry to help the Hospital Authority and society,” said Man Hau-chung, dean of the engineering faculty at the university, who oversees the lab.

Advertisement

“The most important thing is to make it in Hong Kong, and that we can have our own adequate supply.”

Advertisement

Select Voice

Select Speed

1.00x