With new state-of-the-art manufacturing centre facing ‘overwhelming’ tenant response, can Hong Kong find space for innovation sector?

- HK$6.65 billion Advanced Manufacturing Centre is a keystone of government’s re-industrialisation strategy

- But demand may outstrip supply as companies seek local base, and city could find itself short on space for sector that it wants to grow

The operator of Hong Kong’s science park will consider building more advanced manufacturing facilities to accommodate future needs as demand for space at a planned project in Tseung Kwan O is likely to outstrip supply.

The final tally of applications for floor space at the 1 million sq ft Advanced Manufacturing Centre (AMC) – a key component in the government’s re-industrialisation strategy – is expected to be “overwhelming”, according to a source close to the matter.

The source cited preliminary results of a survey conducted by the Productivity Council last year on 500 local and overseas companies across 20 different industries, which indicated “very strong demand and support”.

City can profit from Greater Bay Area scheme, senior officials say

Over a quarter of respondents – about 125 companies – have expressed interest in establishing advanced manufacturing facilities in the city.

Full results of the survey will be announced within this quarter.

The Hong Kong Science and Technology Parks Corporation declined to reveal the number of applications so far but the source said the park may have to consider further development of facilities like the AMC to accommodate future needs.

Pre-leasing of factory space at the state-of-the-art facility is set to begin in the first quarter of the year, although it is not set to open until 2021-22 at the earliest.

The science park operator, which is in charge of the HK$6.65 billion project – approved by lawmakers in 2016 – said foundation works had already commenced and the detailed design of the building was being finalised.

All eyes on Science Park after massive HK$40 billion budget handout

The AMC will help foster “smart production” and “advanced manufacturing”, in line with the government’s aim of heralding a hi-tech industrial renaissance of sorts that would provide a new source of economic growth and jobs.

“Since the AMC is a pilot project, we will gather feedback from the industry for a better [view] of how to contribute to re-industrialisation effectively when the pre-lease starts … in the next few months,” Dr Yiu Hing-leung, head of advanced manufacturing at the park, said separately.

Since 2016, the government has been pushing for re-industrialisation, with the aim to develop “high-end manufacturing based on new technologies and smart production”, given that the sector “does not occupy much land”.

Want to make Hong Kong manufacturing great again? Give us space

But space remains a major factor. In May last year, 95 per cent of sites in the city’s three industrial estates – Tai Po, Yuen Long and Tseung Kwan O – were leased out to 159 enterprises.

Hong Kong-based Computime, which produces smart internet-connected home systems and appliances mainly for the European and US markets, is one firm pinning its hopes on the new Tseung Kwan O facility. It is looking to move some production lines home from the mainland.

The aim was to “grow the company into new product areas that are higher value-added, offering bigger profit margins”, according to Dr King Owyang, the company’s chief executive.

“From a manufacturing standpoint, the focus is not so much on labour costs any more but more on how to implement the complexities ... into a product in a smooth way,” Owyang said.

“We get better technical resource and support in Hong Kong, which is important both in introducing products from an innovation standpoint and production standpoint. I think the AMC is very geared towards this.”

We get better technical resource and support in Hong Kong

He added that the hardware was just as appealing. “They have a ceiling height of at least 6 metres, which lends itself to automation. Our products must also be connected wirelessly to the cloud. In China it will be hard to find a facility like this.”

The company plans to achieve 15 to 20 per cent compound annual growth per year over the next five years, and most would come from Hong Kong rather than expanding its base in China.

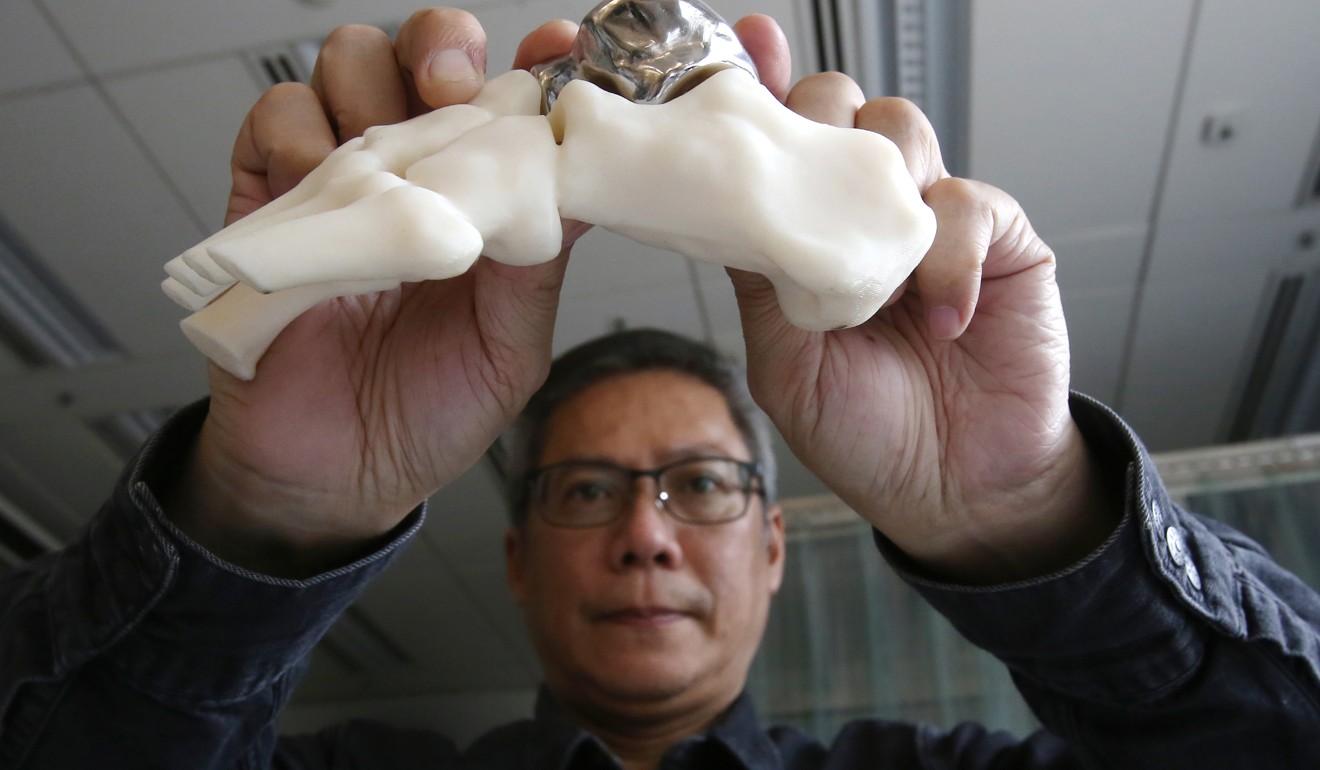

Edmond Yau Wing-fung, founder of Koln 3D, is another applicant. About 20,000 to 50,000 sq ft of floor space for his business could be available if he is successful. “We haven’t heard back yet,” Yau said.

His company is currently the only firm in Hong Kong that can do additive – rather than reductive – 3D printing of medical-grade metal implants. Reductive production refers to when a base material is carved or shaped into its desired form by parts removal, and additive is the opposite.

The machinery he uses is from Japan and is considered military technology. Being in Hong Kong made it relatively easier for him to acquire them.

“It is easier if production is in Hong Kong too. It’s easier to export, get insurance and of course keep your intellectual property safe,” he said. “It is possible to do mass production because the beauty of 3D printing is that I can create nine different products simultaneously.”