Hong Kong’s Chinese University sets up 6 labs under umbrella of InnoHK to drive discoveries in range of areas, from nanobot surgery to automated logistics

- At one facility backed by HK$470 million in funding, professors are combining an MRI machine, CT scanners and robotic arms to assist in surgeries

- Another lab is using machine learning and AI to help streamline clothing manufacturing, with one goal incorporating sensors to turn body language into speech

A Hong Kong university has set up six research centres to drive innovation across a wide range of fields, from carrying out surgery via robots to giving the speech impaired a new way to communicate and even streamlining logistics with new automated processes.

Led by scientists from Chinese University and formed under the government’s InnoHK research programme at the Science Park at Pak Shek Kok, the labs have received hundreds of millions of Hong Kong dollars each in public funding.

University pro-vice-chancellor Professor Sham Mei-har said on Monday the labs aimed to test cutting-edge products that could be marketed to help solve manpower shortages at cargo ports and improve surgical precision.

“Using our existing knowledge base, the labs can elevate research to practical uses and is the biggest step that the InnoHK Centres are taking,” Sham said during a media tour. “It can solve problems in medicine and surgery, logistics, speech impediments or even tailor-make clothing.”

In addition to the scientists based in Hong Kong, the labs have joined up with leading universities across the world, including Imperial College in London and the college of engineering at the University of California, Berkeley.

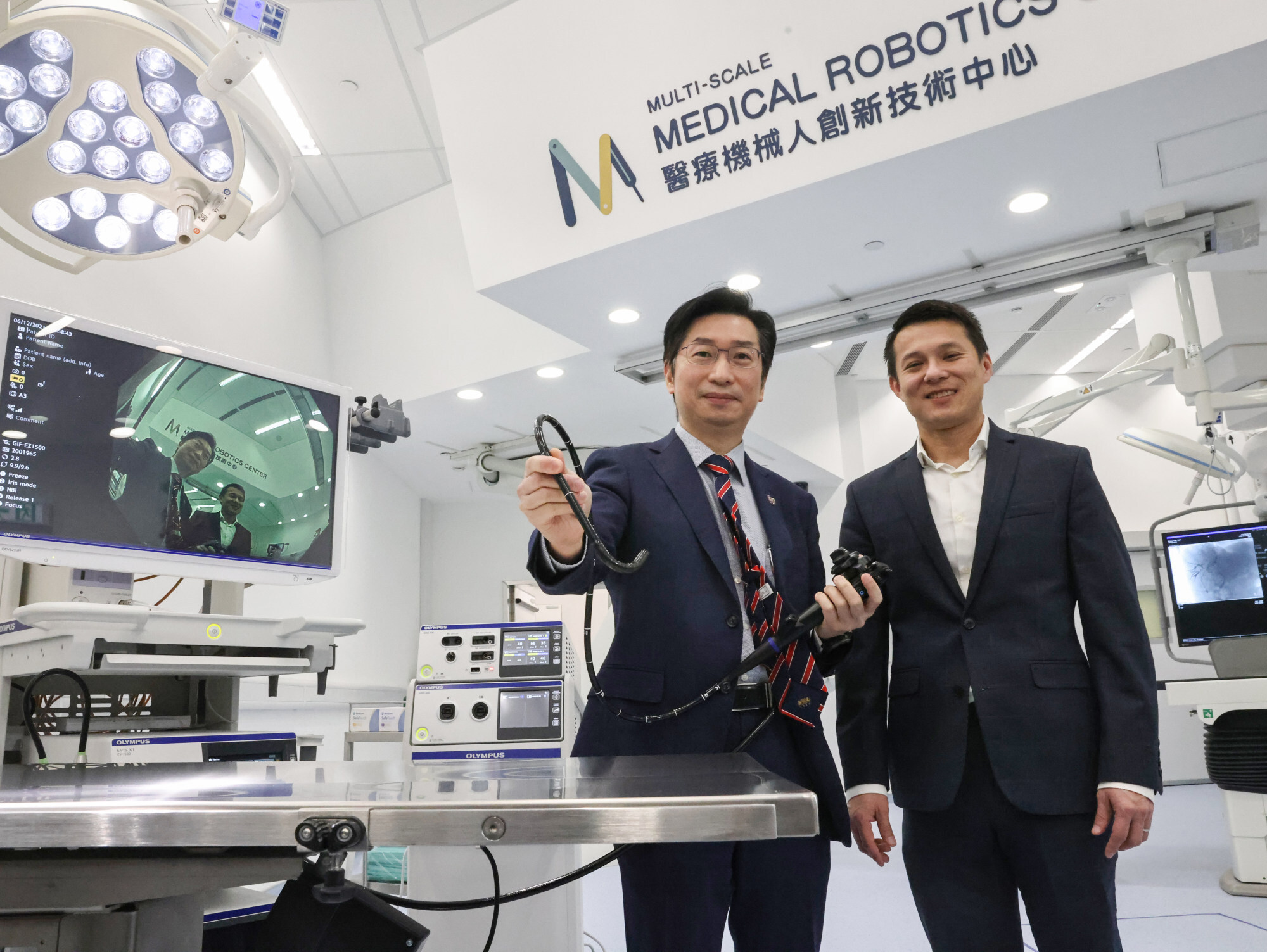

The labs are also helping to foster cross-discipline cooperation, for example, surgeon Professor Philip Chiu Wai-yan has been collaborating with engineering Professor Samuel Au Kwok-wai to establish one of the world’s few – and the first in Asia – multiscale medical robotics centres.

The effort combines an MRI machine, CT scanners and robotic arms to assist in surgeries at a HK$470 million (US$60.3 million) lab that Au called a “dream come true”.

The goal was to allow surgeons to receive real-time imaging of their operation while using the machines to check their work, he said.

“We eventually hope to use a combination of MRI and CT scanning combined with nanorobotics to conduct minimally invasive surgeries without the need for humans to be in the room,” Chiu said. “The goal is to be able to enter any nook and crevice.”

Hong Kong tech incubator urges transformation of local industry

The professors and researchers intend to first test the approach on cadavers and animals such as pigs next year before beginning clinical trials on people.

They hope to run practical tests of previous research in nanorobotics, speeding up a process that usually takes months to mere days or even hours.

Meanwhile, Professor Yam Yeung at the Centre for Perceptual and Interactive Intelligence is focusing on using machine learning and AI to help streamline clothing manufacturing.

The technology could be used to create form-fitting sportswear, posture correcting clothes or even wearable items that incorporate sensors to turn body language into speech.

The centre is running experiments using AI to analyse the speech patterns of people whose language abilities have been impaired by a stroke or Parkinson’s disease, for example.

‘Made in Hong Kong’ is coming back stronger than ever

Professor Helen Meng Mei-ling, the lab’s principal investigator, said the programmes could contribute to research into ways the brain deteriorated.

At the Hong Kong Centre for Logistics Robots, Professor Liu Yunhui envisions using robots to carry out specific repetitive tasks in warehouses and factories that might wear down the attention of workers and expose them to injury risks.

The robots developed by his team could also be deployed at ports to help with removing heavy metal clasps used to lift and transport cargo containers, a dangerous and tiring task which few younger workers appear interested in taking on.