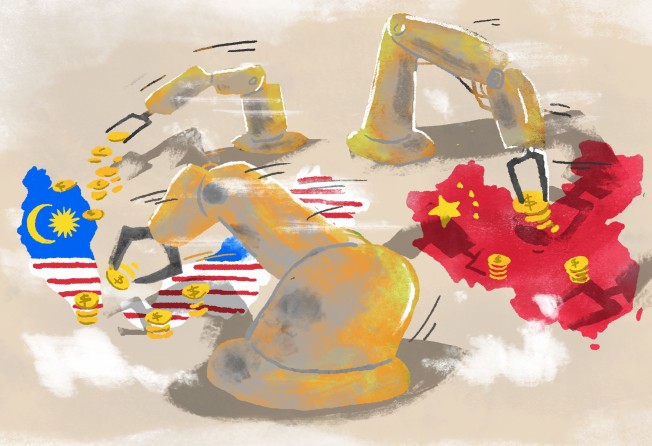

China manufacturing exodus, US trade war tariffs spur investment in Malaysia’s ‘Silicon Valley’

- Malaysia’s electronic industry has seen a surge in investment as US and Chinese companies look to escape tariffs placed on each other’s products

- Reliable infrastructure, established supply chain and skilled workforce give it an edge over other parts of Southeast Asia as manufacturing hub, Malaysian companies say

Nearly two decades after losing its shine to China, the “Silicon Valley of Southeast Asia” is regaining its competitive edge as a growing number of multinational firms look to Malaysia to escape the effects of the US-China trade war.

The Malaysian island of Penang has seen a surge of foreign investment over the past 18 months, with companies operating in China scrambling to take advantage of its long-established electronics sector and evade US tariffs that have been slapped on hundreds of millions of dollars of Chinese exports.

With China “no longer cost competitive” for some businesses, enquiries about establishing factories or relocating operations to the Southeast Asian nation have been rising, said Heng Huck Lee, CEO of Globetronics, which designs and manufactures a range of electronic products for multinational firms.

“In the last 18 months Penang has been a very active location, with lots of Chinese manufacturers, lots of US companies, looking into relocating and expanding their facilities here,” Heng said. “If you were to look back into 2019, Penang’s foreign direct investment was the highest in many, many years.”

At its factory in the Bayan Lepas Free Industrial Zone, Malaysia’s first free-trade zone, Globetronics’ employees dressed in white spacesuits, slippers and masks move about rows of state-of-the-art die attachment machines used to bond semiconductors to circuit boards. At the end of the production line, the tiny sensors will be shipped to a client in the US to be used in phones and tablets.

Trade tensions between the world’s two largest economies have been good for business, Heng said. Customer orders have increased over the past year and a half since the tariff war began, and so had enquiries from potential clients. A US partner with two manufacturing bases in China had even relocated part of its operation to Globetronics’ third factory in Kuala Lumpur due to the “urgency” of the tariff situation, he added.

“I think 2020 is going to be better than 2019,” said Heng, who is also a member of the government’s Malaysian Investment Development Authority’s (Mida) electronic advisory committee. “Whatever we are seeing directly and indirectly today, Malaysian manufacturing companies should continue to see some additional spillover.”

Whatever we are seeing directly and indirectly today, Malaysian manufacturing companies should continue to see some additional spillover

Penang clocked up 12 billion Malaysian ringgit (US$2.94 billion) in foreign investment in the first 10 months of 2019, an increase of 456 per cent from 2.1 billion ringgit (US$514 million) a year earlier, according to InvestPenang, the principal investment promotion agency of the state government. The number of new jobs created over the same period nearly doubled to 15,013.

Penang saw major investments from US chip maker Micron Technology, which announced that it would spend 1.5 billion ringgit over five years on a new solid-state drive assembly and test facility, as well as American firm Jabil Circuit and British medical device maker Smith+Nephew.

Loo Lee Lian, CEO of InvestPenang, said the state was seeing benefits from the trade war.

“Companies are diversifying their geographical bases with the rising trade tensions and tariff imposition. Investors enquiries have also been on an increasing trend,” she said.

The US replaced China as the largest source of approved foreign investment in Malaysia over the first nine months of 2019, spending US$5.9 billion, a huge leap from US$889 million a year earlier, according to Mida. Chinese investment, meanwhile, halved in value to US$1.7 billion from US$3.5 billion in the previous year.

“The tariffs imposed on China raises the possibility of trade and investment diversion to Malaysia,” said Zalina Zainol, a Mida spokesman, adding that Malaysia was becoming increasingly selective in its investment agenda.

The government was targeting sectors with high growth potential and low labour-intensity, Mida said, including the chemical industry and producers of machinery, medical devices and aerospace.

But one of the biggest winners is the electronics sector, which already accounts for the biggest share of Malaysian exports, some 38 per cent between January and November 2019, according to government figures.

The tariffs imposed on China raises the possibility of trade and investment diversion to Malaysia

Since Penang’s Bayan Lepas industrial zone was established on reclaimed mangrove swamp, padi fields and coconut plantations in 1972, the electronics industry has developed into a key driver of the Malaysian economy.

By the mid-1970s, multinationals like Intel, Motorola, Hitachi had all established factories in Penang, lured by government tax incentives aimed at attracting foreign investment in export-led production. Malaysia’s electronics sector grew rapidly over the next two decades until losing momentum in the mid-1990s as foreign companies turned to China to take advantage of cheap labour.

Lee Hung Lung, chairman of Penang-based Hotayi Electronic, remembers the period as one full of “very big challenges”. Just a few years after the Taiwanese businessman built his first factory in 1992, many of his competitors started relocating to mainland China.

“Chinese labour was cheap – they did not need machines, they could mount printed circuit boards by hand,” he said.

Hotayi survived by investing in high-end, automated manufacturing, Lee said. Now, while numerous multinationals are looking to relocate due to rising costs in China, Hotayi has seen an uptick in enquiries from foreign firms and last year officially opened a new 350,000 sq ft factory worth 1 billion ringgit (US$245 million) in Penang’s newest industrial estate, Batu Kawan.

The spotless, white-walled factory, which includes a golf putting green between buildings and a recycled rainwater system, now employees the bulk of the company’s 1,000 plus workers.

“Many [companies] are looking outside China to produce their products due to the trade war,” Lee said. “Among Southeast Asian countries, Malaysia is one of the best. Semiconductor manufacturing in Malaysia has been operating for more than 40 years already – so they have very good supply chain and talent.”

The US-China trade war has seen a flood of companies leaving China for tariff-free manufacturing bases in Southeast Asia, particularly to neighbouring Vietnam.

But Heng, from Globetronics, said Malaysia’s 40-odd years of industrialisation in hi-tech work and its reliable infrastructure sets it apart from other countries in the region.

“You look at Vietnam, from the technical workforce to the people that can do product development to the design, I don’t think they are there,” Heng said. “Likewise with Indonesia and likewise to a certain extent in Thailand.”

Malaysia jumped to 12th from 15th position among 190 countries on the World Bank’s Doing Business Report 2020, outperforming every Asean country except Singapore.

Still, the trade war has left Malaysian-based businesses grappling with a number of challenges.

China’s economy grew at 6.1 per cent in 2019, the slowest pace since political turmoil ravaged the country in 1990. Reduced demand from China and a slowdown in global semiconductor sales contributed to a 4.9 per cent annual decline in Malaysian electronic exports in the third quarter of 2019, according to the country’s central bank.

And despite this month’s phase one trade deal, souring bilateral ties between China and the US have raised the possibility of a tech war that some say could have an even larger impact than the current tariff battle.

The US government has already banned the export of crucial American electronic components to a number of Chinese firms, including Huawei, a leader in 5G mobile technology. The prospect of decoupling between the US and China could leave Malaysian manufacturers walking a tightrope between the two superpowers.

Sooner or later the trade war will be over, but I think the semiconductor Cold War has just started.

“Sooner or later the trade war will be over, but I think the semiconductor Cold War has just started,” said Sang Beng Ng, the CEO of Penang-based Aemulus, which produces automated semiconductor testing equipment. “If you stand too obviously in one camp, then the other camp will ask you what side you are on.”

Even with the trade war de-escalating for now, business leaders in Malaysia said the ripple effects were likely to be felt throughout Asian economies for some time to come.

The political uncertainty – which has helped fuel a slowdown in global trade and a slump in investment – was clouding decision making.

“Everybody is in ‘wait and see’ mode,” added Heng. “While we think we are benefiting in the short term, in the long term I hope to see more stability.”