Burgers made from fish food on the way as Singapore food tech start-up develops microalgae meat substitute

- Sophie’s Bionutrients uses microalgae to develop 100 per cent sustainable alternative protein products

- Its protein flour concentrate can be used in everything from meat analogues to drinks and requires a fraction of the inputs needed to grow soy and other legumes

Plant-based meat alternatives – from burger patties and sausages to minced pork and even shrimp – are an increasingly common sight on supermarket shelves and dining tables across Asia. Indeed, a recent study projects that the market for meat analogues in Asia-Pacific will grow by 25 per cent over the next five years.

Most of these products are derived from mainstream ingredients such as soy, wheat, peas and gluten – and for good reason. For instance, the Impossible Burger is chiefly made from soy protein concentrate, while Omnipork’s pork analogues are produced using a blend of peas, soy, shiitake mushrooms and rice.

“Such crops carry the advantages of a more mature supply chain and decades of knowledge on how to utilise them for alternative protein purposes,” explains Mirte Gosker, acting managing director of The Good Food Institute Asia Pacific.

In contrast, Singapore food tech start-up Sophie’s Bionutrients is banking on an entirely different ingredient: microalgae – single-cell microorganisms found in fresh water and salt water.

Thousands of microalgae strains exist, and some already feature in our diets. For example, spirulina is often added to health drinks because of its purported antioxidant and anti-inflammatory properties.

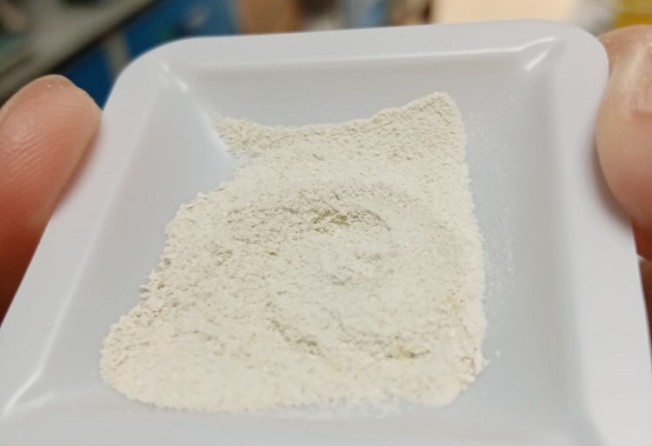

However, Sophie’s Bionutrients may be the first company in the world to develop a plant-based protein flour from microalgae, which it claims can be used for a wide range of food applications – from making meat analogues to drinks.

The company is named after its founder Eugene Wang’s daughter, Sophie, who is allergic to shellfish. Before launching Sophie’s Bionutrients in 2017, Wang ran a plant-based seafood company called Sophie’s Kitchen in Sebastopol, California.

“Back then, my customers kept asking me if my products have the equivalent nutritional value of seafood,” he says. “As we were using ingredients like potato starch and pea protein, the short answer was no. That got me thinking – how can people get nutrients from the ocean without using animals?”

Wang soon realised that fish and shrimp obtain their nutrients by consuming microalgae – and so the idea for Sophie’s Bionutrients was born.

The company has since gone from strength to strength: in 2019, it was awarded a S$1 million (US$750,000) grant from The Liveability Challenge, a global entrepreneurship initiative; in December 2020, it was selected as a finalist for FoodTech 500, an annual list of companies shaping the food industry.

Expansion plans are under way: it aims to open a production facility in Singapore this year, which Wang says will produce at least 10 tonnes of protein flour per month. This will be supplied to other food companies; for instance, Singapore manufacturer Ha Li Fa will use the flour to produce plant-based “crab cakes”, which are awaiting halal certification and will hit the shelves late next year.

According to Wang, the health and nutritional benefits of microalgae are numerous. “Microalgae have the best and most complete nutrients among all the microbes,” he says. “They contain all of the essential amino acids – far more than most commercially available fish – as well as different types of vitamin B.”

Professor William Chen, the Michael Fam chair professor and director of food science and technology at Nanyang Technological University in Singapore, concurs. “There is a wide spectrum of microalgae strains – some rich in proteins, others rich in lipids and micronutrients. These properties make microalgae an attractive option for future foods,” he says. “The key is to select the right strain for the right need.”

In addition, studies show that microalgae have a higher protein yield than terrestrial crops such as soybeans and other legumes.

They have environmental benefits, too. Sophie’s Bionutrients’s microalgae, which include two strains of chlorella, are fermented in bioreactors in just three days, using just a fraction of the water and energy required for conventional agriculture – and without any fertilisers, herbicides, antibiotics or growth hormones.

The fact that they can be cultivated indoors makes them highly resilient to the effects of climate change. Plus, the process is highly space-efficient, requiring only 0.02 hectares of land to produce one tonne of protein. “Simply put, we are running out of space for animal farming and agriculture,” says Wang. “Growing foods in bioreactors will be the future.”

Other companies are following suit. This month, after a decade of research, Canadian microbial ingredient company Smallfood unveiled what it dubs a “more perfect protein” – a protein powder derived from an undisclosed strain of microalgae.

The powder can be produced via biomass fermentation in just seven days, with minimal land, water and energy requirements. As with Sophie’s Bionutrients, Smallfood’s powder will be sold directly to other food and drinks companies, with potential applications including energy bars and meat analogues.

“We need to usher in food production systems that are more resource-efficient and scalable than conventional agriculture and livestock,” says Smallfood founder and CEO Marc St-Onge. “Microbes can help feed our growing population while easing the burden on natural resources.”

Granted, it might take some time for microalgae-based protein to truly enter the mainstream.

“Every new plant-based ingredient carries some built-in flavour notes that may clash with the desired product, and thus must be masked. This could hinder adoption by limiting application versatility,” says Gosker. “However, this is a temporary hurdle that we are confident alternative protein producers will overcome.”

Indeed, Smallfoods says its protein powder has a “neutral taste, with no grittiness and an excellent mouthfeel”.

As microalgae are still a relatively new protein source, Chen highlights the need for proper safety assessments before introducing them to consumers’ diets.

Despite these challenges, microalgae could well be the future of food – especially in a world where climate change is a pressing problem, and where an estimated one billion people suffer from protein deficiency.

“The ability to efficiently produce protein via fermentation could almost single-handedly resolve the global protein deficit,” Gosker says. “Also, by continuing to expand the range of raw materials used to make plant-based meat, producers can choose the ingredients that best complement their local agriculture and business ecosystem.”