US eager to recycle lithium batteries so it doesn’t have to buy them from China

- Officials in Washington are portraying the drive to develop recycling technology as a ‘national security’ issue

The US government will lead an ambitious effort to develop technologies to recycle lithium-ion batteries from electric vehicles, mobile phones and other sources to ensure a reliable and affordable supply of metals crucial to battery production in anticipation of soaring global demand and potential shortages, Department of Energy officials said on Friday.

Calling the effort a national security issue, the agency announced a US$15-billion, three-year research and development project at Argonne National Laboratory outside Chicago. The collaboration between government labs and universities is also an attempt to catch up with China and other countries that manufacture and recycle lithium-ion batteries, including those shipped back from the US, officials said.

US dependence on other countries for metals such as lithium, cobalt, nickel and graphite, as well as finished batteries, “undermines our national security” because the source countries are not always close allies, said Daniel Simmons, assistant secretary of the Energy Department’s Office of Energy Efficiency and Renewable Energy.

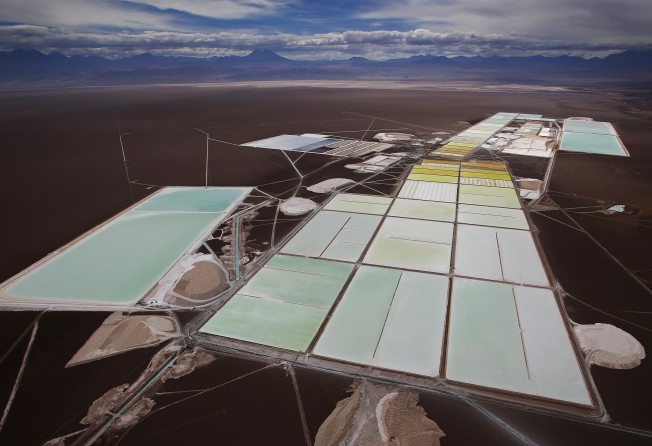

Lithium salts primarily are extracted in South America and African countries and Australia, and cobalt largely mined in the Democratic Republic of Congo, experts said. The US has a strained trading relationship with China, which produces a large share of the batteries and has been aggressively recycling them to recover metals it otherwise would have to import.

But the demand for lithium-ion batteries is also driving the effort. With US carmakers set to expand production of electric vehicles over the next 10 years and batteries from existing electric vehicles nearing the end of their useful lives, it’s time to figure out how to recycle them in the US, said Jeff Spangenberger, director of the new recycling centre, called the ReCell Centre.

The centre will focus on developing a process to allow recovered material to be put directly back into new batteries without having to break it down into their core components.

“We’ve done a lot of analysis … and if we don’t recycle, we will run out of materials,” Spangenberger said. “If we had a steady supply from recycled materials, we would reduce the risk.”

But recycling raw materials will not do the US much good if it does not also make the batteries and finished products here, experts said.

“There is no sense to recycle in the US and not be able to use in the US … Otherwise you have to sell to China because that’s where they make the batteries,” said Hans Eric Melin, a consultant at London-based Creation Inn who studies the lithium-ion battery industry. He also pointed out the need to collect enough batteries for recycling in the first place.

Melin said recycling will also become increasingly important as more companies use lithium-ion batteries in products. Big companies might be able to source enough raw materials, he said, but second-tier companies may have to rely on recycled material.

In 2018, about 100,000 tons of lithium-ion batteries were recycled globally, Melin said, adding that about 14,000 tons of cobalt was recovered from the batteries, or about one-fifth of the market for the metal.

James Greenberger, executive director of NAATBatt, a consortium of companies promoting US advanced-battery manufacturing, said it’s important that recycling is affordable enough that manufacturers of cars and other products will not have to pass the costs on to customers.

“Everybody’s waiting for a technological solution,” said Greenberger. “But I think we can absolutely catch up.”