As China embraces electric cars, this start-up is trying to profit from a 60-year-old smart glass technology

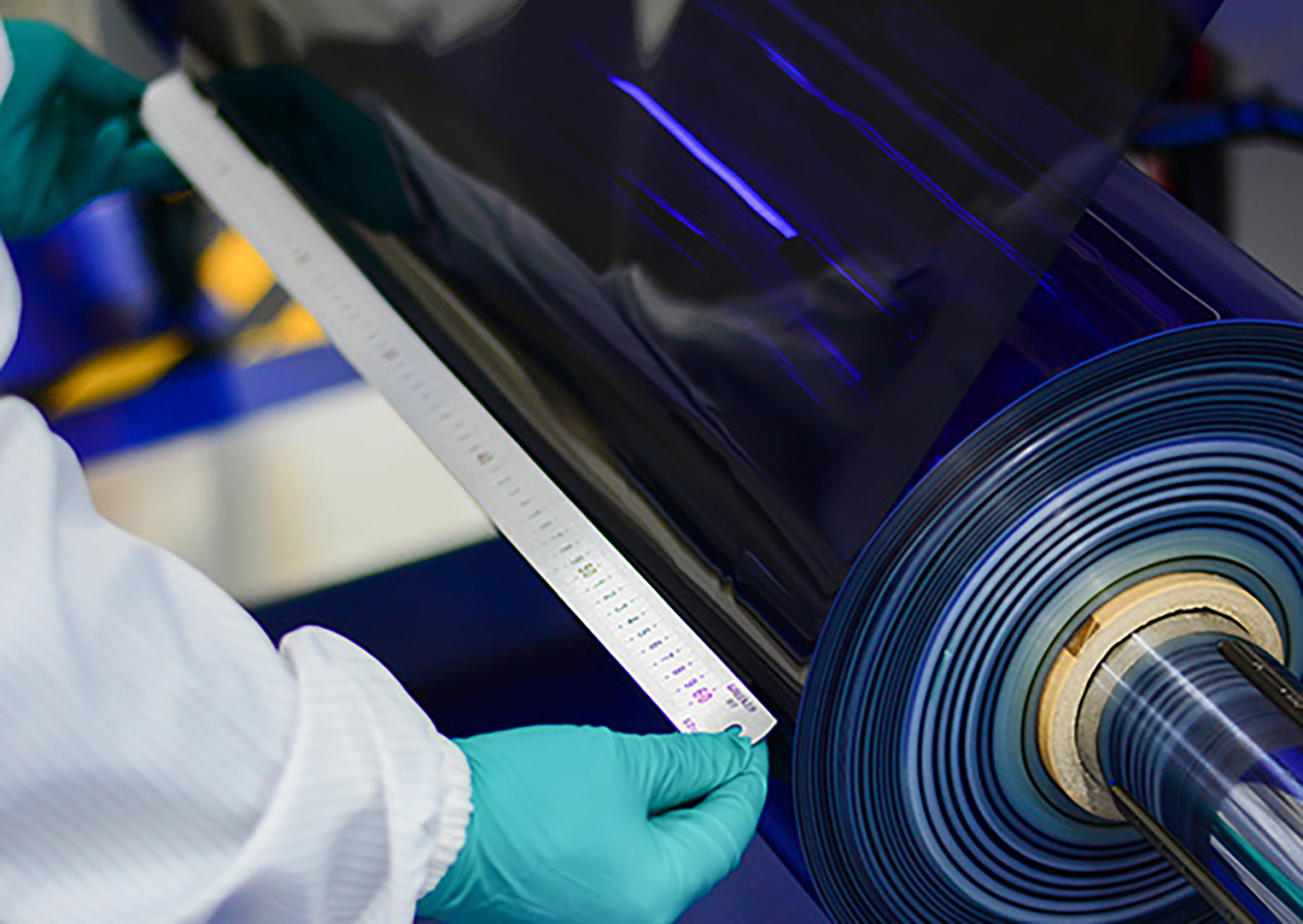

- The technology Ambilight is working on – thin film assembled with proprietary EC materials – aims to solve heat and light problems in glass

- Sunroofs are a popular feature in electric cars, with the sector expected to be worth US$1.5 billion by 2025, according to Guotai Junan Securities

He Jiazhi, a Purdue University chemistry PhD graduate, is on a mission to bring electrochromic (EC) technology for glass out of the research lab and into the hands of thousands of consumers.

The explosive growth of China’s new energy vehicle industry and recent breakthroughs in lab research have offered fresh hope that the technology is ready to be widely adopted. “When we were doing early experiments, we were only able to make it the size of a fingernail … But if we can make it into a technology like [the printing press], where it can be industrialised, the cost will be reduced, making it available to all consumers,” He, the co-founder and chief technology (CTO) officer of Ambilight, said in an interview with the South China Morning Post.

EC technology, which was invented in the 1960s, can change the colour of glass by altering the electric field. However, it still has limited use and has not been commercialised on a large scale.

Xiaomi electric cars to see mass production by next year, founder says

He was inspired by his Purdue professor Mei Jianguo, who also co-founded the company in 2017. Mei, a Richard and Judith Wien Associate Professor of Chemistry at Purdue, obtained his doctorate at the University of Florida in 2010 and worked as a postdoctoral fellow at Stanford University in 2014, according to his official bio.

“My professor told me our research should lead to discoveries that will be either in textbooks or in the market, or even better in both. That inspired me,” said He.

The technology Ambilight is working on – thin film assembled with proprietary, advanced EC materials – aims to solve two problems; heat and light. “For heat insulation, our technology will absorb part of the sun’s energy, and the glass will reflect some infrared. When the sun becomes very harsh, the glass will turn dark, but if we want to see the scenery outside, we can turn the glass lighter,” He said.

The 7-year-old company is eyeing the growing car glass industry. Sunroofs are a popular feature in electric cars, with the sector expected to be worth 10.6 billion yuan (US$1.5 billion) by 2025, according to a report by Guotai Junan Securities. In 2021, Tesla’s Model Y offered a glass sunroof measuring 1.4 square metres, while Chinese EV carmaker Nio had a glass roof of more than two square metres in its EC6.

Still, Tesla received widespread criticism for the size of its Model Y sunroof. “The sunroof is way too hot in the summer … when the weather gets hot, the top layer [in the car] is full of hot air,” a Bilibili live-streamer said in a video.

Nio collaborated with Ambilight to develop a smart dimming sunroof for its upcoming EC7 model, providing the core colour-changing material, consisting of black-grey EC film for the canopy. In an article published on its website, Ambilight said it was a “major technological breakthrough in the field of electrochromic technology”.

As Ambilight quickly expanded, it has attracted investors’ attention in recent years. From only around 20 staff in 2019, the company now employs 500 people. It completed A-round financing in 2020, followed by another two rounds in 2021. In its latest C-round, the company said it raised “hundreds of millions of US dollars” led by Warburg Pincus. BYD and Nio also participated in the round.

China’s premium EV makers report stronger sales in February

He, the co-founding CTO, said the company will have another round of financing this year, without elaborating on the details.

To get its new film into the highly concentrated car glass market, Ambilight will likely have to work with dominant players like Fuyao Glass Industry Group, founded in 1987 by billionaire Cao Dewang. The top six players in the global car glass market accounted for 98 per cent of it in 2020, according to the Guotai Junan report.

Start-ups like Ambilight can use their advantages to collaborate with glass giants like Fuyao, according to Zhang Shiyue, an analyst at Leadleo. For example, an EC glass product Fuyao released last year used technology provided by Ambilight, she noted.

“Start-ups can use their technology highlights to compete and innovate, and use it to develop long-term cooperation with glass giants, using [the bigger company’s] resources to improve their competitiveness,” Zhang said.

Zhang Xiang, a visiting professor at the engineering department of Huanghe Science and Technology University, said EC thin glass technology was still very new and might be too expensive. “Ordinary consumers may not have a high need for this kind of glass,” he said.

Besides applications in the car industry, Ambilight is also looking at consumer products like augmented reality glasses, and the architecture industry. “For glass facade buildings, if we can give the building the function of modulating light and heat transmission, it can potentially help to save 30 per cent on energy costs,” Zhang said.

Outside China, the company is also looking at North America, Europe, Japan and the South Korean market. “The overseas auto industry has a longer verification cycle, compared with mainland [China], but we are also collaborating with each other,” He said.

Thinking back to the early days of 2019, He said he was barely at home because of the pressure to deliver its first commercial product. “Mostly I finished my day at 2 or 3am that year because I had no experience in industrial production after I finished my PhD. It was a process [of going] from 0 to 1,” he said.

“There will be a lot of moments of self doubt, but I never thought about giving up. Because our team developed rapidly, sometimes I [wonder] whether we are on the right track, [going] in the right direction,” he said.