Will Hong Kong’s largest private recycling plant solve woes over plastic bottles waste?

- German recycling giant Alba intends to create food-grade material from waste plastics that can be fed back into local manufacturing sector

- But green group says challenge will be on how to collect waste from community and feed plant

Hong Kong’s largest private plastics processing and recycling plant is expected to start taking in discarded drink bottles and turning them into safe materials that can be used with food products next year.

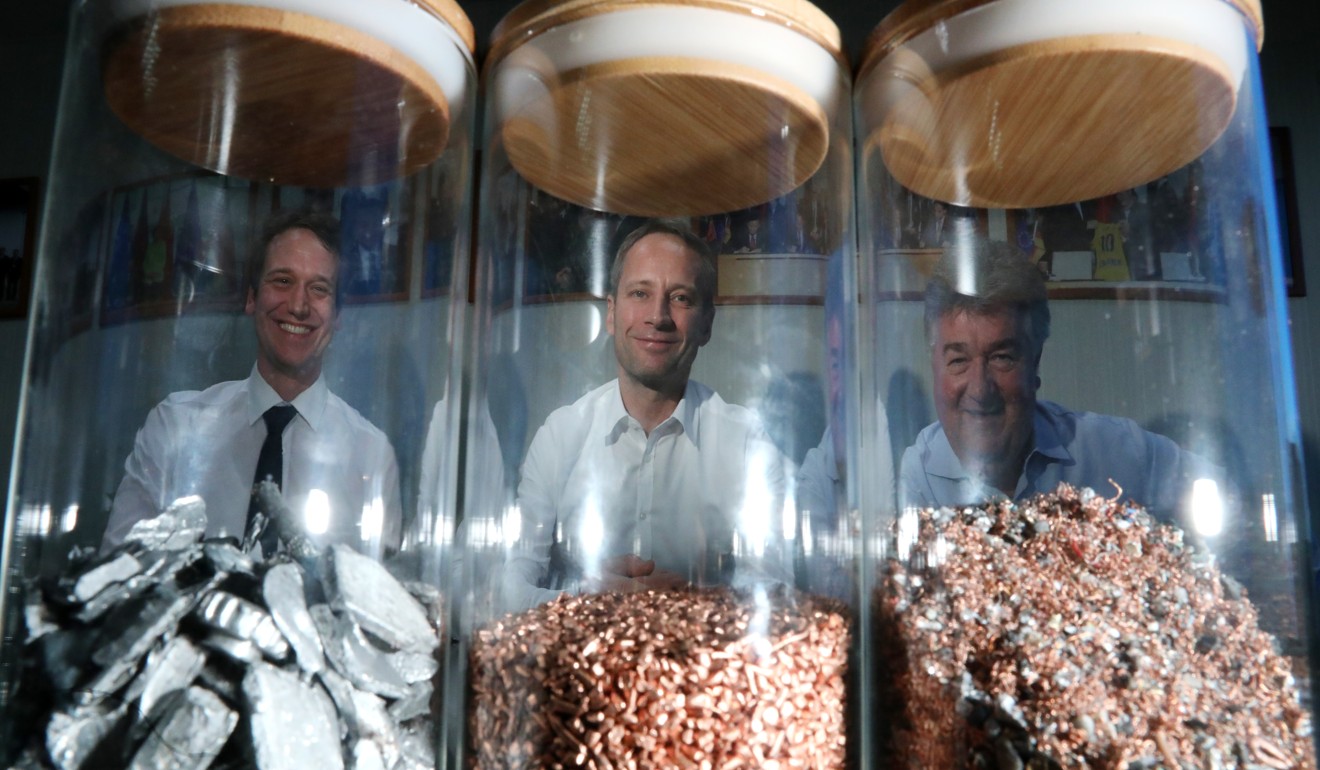

Alba Group, the German recycling giant tasked with running the proposed facility in Tuen Mun’s EcoPark, said the plant would be the first of its scale to turn two common forms of household plastic waste into non-toxic recycled material.

The joint venture, which involves Swire Beverages and Baguio Waste Management & Recycling, will eventually build enough capacity to handle the entire domestic supply of recoverable waste bottles, according to the group.

Industrial waste in landfills up a fifth as China-bound rubbish piles high in Hong Kong

The plant’s expected completion in 2020 will coincide with mainland China’s plans to shut its doors to all forms of solid waste imports, on top of the 24 types already banned since last year.

“So far Hong Kong doesn’t have much large-scale recycling for plastics but we are talking about professional recycling on a level you won’t find anywhere else here,” Alba Group CEO Axel Schweitzer, told the Post in an interview.

We are talking about professional recycling on a level you won’t find anywhere else here

Most recyclers did not have the size or economies of scale to drive industrial change and make recycling profitable, Schweitzer said. “It needs to be profitable to be sustainable.”

The plant, spanning 6,500 square metres, will have two production lines – one for Polyethylene terephthalate (PET) flakes and another for high-density polythene (HDPE) pellets – and equipped with near-infrared technology that can sort waste by material, plastic grades and colours.

It is unknown at this stage how much the facility will cost or what its daily capacity is.

PET is what most drink bottles are made of and HDPE is used in containers for shampoo or household cleaners.

End products could be exported as clean raw material, or even used to supply the local bottling industry – closing the loop to form a true “circular economy” – and avoid millions of bottles being sent to landfills each year, Alba stated.

“The plant will need to go through a period of ramping up, to implement the system and collect enough material because this is all new to Hong Kong,” Schweitzer said. “But the ultimate goal should be, if needed, to cover all of the domestic market.”

China’s waste ban: What next for city’s rising mountains of trash?

The mainland’s move to shut out solid waste imports and control its waste management has been problematic for Hong Kong. The city has insufficient space and facilities to process its own waste, nor the market to absorb clean recycled plastic.

“The vision should be to not have any urban plastics sent to landfills in Hong Kong,” Schweitzer said.

Mandatory waste charging will provide a much-needed boost to recycling too.

Hong Kong generated 50,000 tonnes of PET bottle waste in 2017, most which were sent to landfills, and only 8.5 per cent was recovered for recycling. Around 3,660 tonnes were exported, almost exclusively to the mainland before the ban.

A Swire spokesman said: “We understand the urgency of establishing a local recycling infrastructure in the city for facilitating plastic waste recycling, and we believe local recycling of PET is an essential step towards creating a closed-loop model for recycled PET in Hong Kong.”

Hong Kong to pay for recyclers to collect plastic waste in trial scheme covering homes, offices and schools in 3 districts

Alba business director Tobias Huinink said that in the future, the company would look into expanding its scope to other plastics such as polypropylene – used for yogurt tubs – and low-density polythene, used in lightweight packaging.

“It can’t be done like in the PET/HDPE venture as a private initiative, but hopefully it could be a project similar in model to the [government’s electrical and electronic waste equipment] plant,” he said.

Alba has been operating the government’s main treatment facility for waste electronics and appliances since a “polluter pays” legislation – which mandates producers to handle recovery and recycling – covering five types of appliances went into effect last year.

Edwin Lau Che-feng of The Green Earth, an environmental advocacy group, said money could buy the best sorting and processing technology in the world but at the end of the day it was all about how to recover and collect the waste from the community.

The key is how to secure enough feedstock to keep the machines running

“The key is how to secure enough feedstock to keep the machines running,” he said. “How would they incentivise people to return bottles or frontline collectors to recover them? Will they offer payments?”

The Environmental Protection Department is studying a polluter-pays scheme for plastic bottles but Lau said he did not expect that to kick in before the factory’s opening.

He warned that even with its network of tricolour recycling bins, the government’s collection rate for plastic bottles was low.

In December, Hong Kong’s major drink manufacturers, including Swire Beverages, made an unprecedented pledge to work with green groups and raise the recovery percentage of single-use bottles and containers in the city from single digits to more than 70 per cent in just six years.